The latest research study released by Worldwide Market Reports on “Regenerative Braking Energy Absorption Device Market 2024” holds that this market will witness immense growth during the forecast period 2024-2031.

- This report offers an in-depth analysis of the market size, share, growth, opportunity, competitive landscape, analysis, segments & sub-segments, and forecast.

About Regenerative Braking

Regenerative braking is an important mechanism in electric vehicles that increases their energy use efficiency.

- A Brake System: Regenerative braking is one type of dynamic braking. This system is designed to convert the kinetic energy of the wheels to a form that can be stored and used for other purposes.

- These systems are also called kinetic energy recovery systems.

- Methods Used: There are multiple methods of energy conversion in regenerative braking systems including spring, flywheel, electromagnetic and hydraulic.

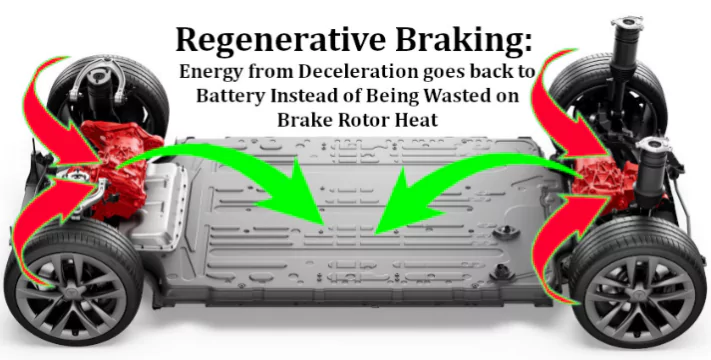

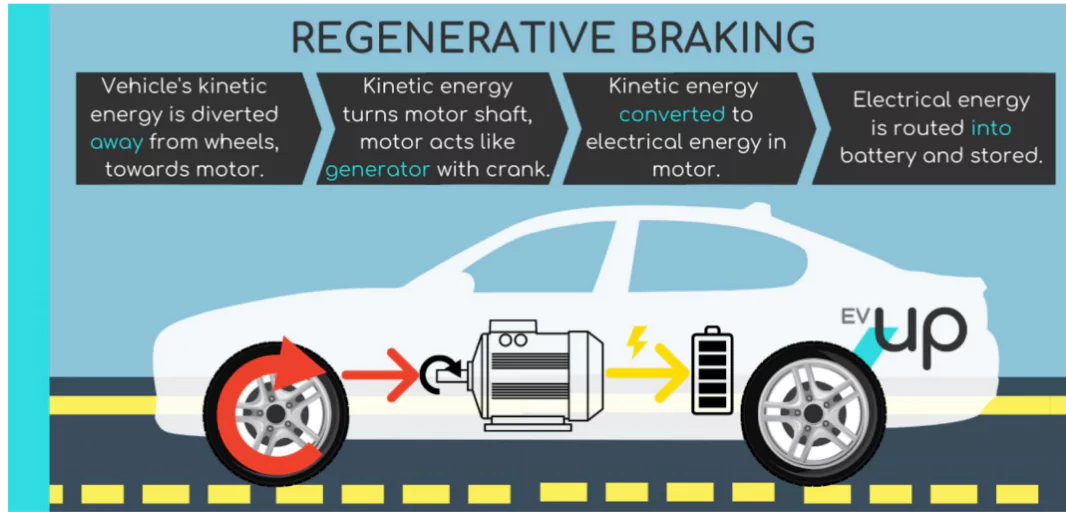

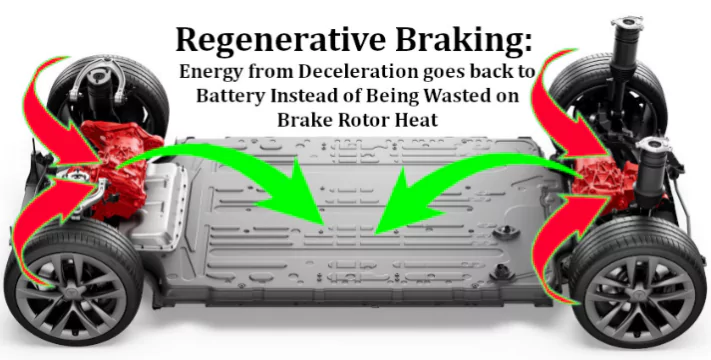

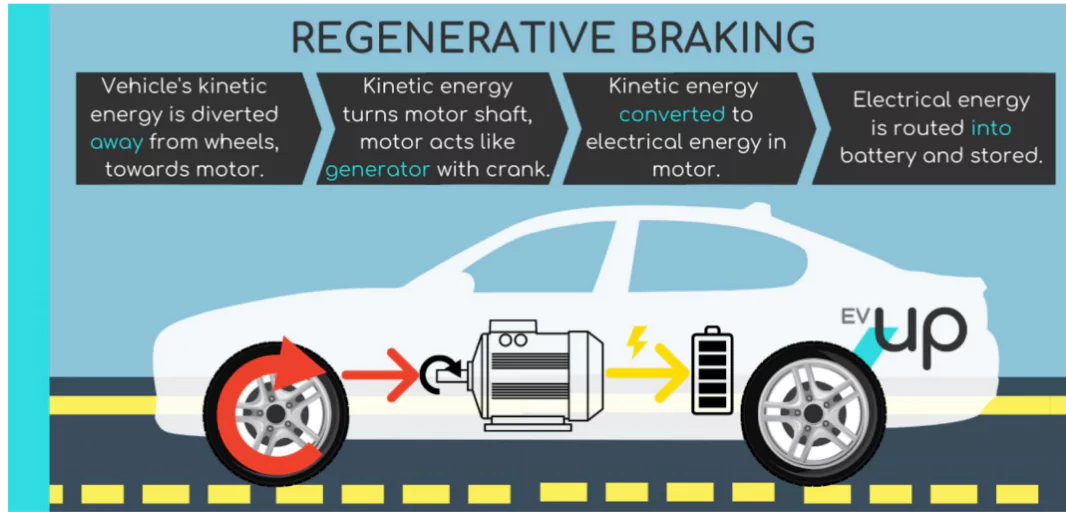

- Working: During regenerative braking, the motor operates as a generator, turning mechanical energy back to electrical energy.

In the electric vehicle, an electric current will be produced as the vehicle brakes, which is stored separately in a battery. In some other vehicles, especially trains, the current is fed back into the traction motor.

In the electric vehicle, an electric current will be produced as the vehicle brakes, which is stored separately in a battery. In some other vehicles, especially trains, the current is fed back into the traction motor.- When the electric vehicle moves, the battery powers an electric motor that propels the vehicle, converting electrical to mechanical energy. This motor is called the traction motor.

- Significance: It creates a process in which at least part of the energy delivered to the vehicle’s wheels can be recovered in a situation when the vehicle does not need it.

Enroll now for UPSC Online Course

Downsides of Regenerative Braking

While it is a simple energy recovery mechanism, regenerative braking has some downsides.

- Need for Conventional System: It alone often does not suffice to bring an electric vehicle to a halt. It has to be used together with a conventional system that dissipates some of the kinetic energy as heat.

- Due to the maximum recharging rate of the circuit and the capacity of the battery, the braking force from an electromagnetic type RBS is always limited. Hence, a traditional friction brake system is required to convert the excess energy from the vehicle.

- The friction brake can also prevent the loss of braking ability in the case of RBS failure.

- On Backsliding: Such a system is also required to prevent vehicles from backsliding downhill, which many regenerative brakes would not prevent.

- Impact on Energy and Fuel Consumption: RBS can only be installed on driving wheels since a drive train is required for energy recovery. The waste heat is not significantly reduced unless the vehicle is an all wheel drive model.

- Although RBS can improve fuel economy under start-and-stop driving conditions, it may have a negative effect on fuel consumption during highway cruising.

- The amount of energy a regenerative brake can recover drops as the vehicle’s velocity drops as well. A regenerative brake can be beneficial for an electric vehicle’s energy-use efficiency in stop-start traffic.

- Reliability on Control Units: The design of RBS involves varieties of sensors and logic control units to adjust the operation of RBS.

- The reliability concern of these electrical parts should not be neglected.

Other Ways to Recover Energy

Following two ways are suggested to recover energy:

- Battery or Supercapacitor: The design of a regenerative brake depends on the energy form to which the mechanical energy from the wheels is to be converted. An electric vehicle funnels it into a generator and obtains a current, which is stored in a battery or a supercapacitor.

- Flywheels: The mechanical energy can be used to increase the angular momentum of a rotating flywheel. Flywheels are especially useful because they can receive energy much faster than other such systems.

- For every unit increase in speed, they also store exponentially more energy. The flywheel can be linked to a reciprocating engine to manage or augment its output, like in Formula One racing, or to a gyroscope to help submarines and satellites navigate.

Check Out UPSC CSE Books From PW Store

About Braking

Braking is the mechanism by which an automotive vehicle in motion slows down.

- Slowing of Kinetic Energy: A vehicle moving faster has more kinetic energy than a vehicle moving slower, so the process of braking removes (mostly) kinetic energy from the vehicle. The law of energy conservation means this removed energy has to go somewhere.

- Example: The disc brake is one type of mechanical brake that works by pressing brake pads against a disc attached to spinning wheels, and uses friction to convert some of the wheels’ kinetic energy into heat.

- This is why the discs of disc brakes have holes cut into them, to dissipate heat better.

- Induction Brake: A magnet induces circular electric currents in a spinning wheel and these currents produce their own magnetic field, which opposes that of the external magnet that acts like a drag on the wheel and forces it to slow down.

- In terms of energy, the metal resists the flow of the circular currents and dissipates heat.

- Rheostatic Braking: The current is sent to an array of resistors that dissipate the electrical energy as heat.

- It is often necessary for a vehicle to have both regenerative and rheostatic braking in case the electrical energy recovered can’t be stored or used right away.

How does a Motor become a Generator?

A motor converts electrical energy to rotary motion and in a generator, mechanical energy from an external source can be fed to the rotor to induce a current in the stator.

- Construction: A motor has two essential parts: a rotor (the thing that rotates) and a stator (the thing that’s stationary).

- In a rudimentary design, the stator consists of permanent magnets or electromagnets while the rotor consists of current-carrying wires coiled around in loops. The stator surrounds the rotor.

- Working: When a charged particle, like an electron, moves inside a magnetic field, the field exerts a force on the particle called the Lorentz force.

- Whether the force will push or pull the wire in which the electron is moving depends on the direction of the electric current.

- The current at the coil’s two ends moves in opposite directions, so the magnetic fields imposed by the stator will push on one end of the coil and pull on the other.

- And these opposing forces will continue to act on the two sides of the rotor until the voltage across the wire is constant.

- Output: By switching the traction motor between these two configurations, an electric (or hybrid) vehicle can implement regenerative braking.

|

![]() 9 Jul 2024

9 Jul 2024

In the electric vehicle, an electric current will be produced as the vehicle brakes, which is stored separately in a battery. In some other vehicles, especially trains, the current is fed back into the traction motor.

In the electric vehicle, an electric current will be produced as the vehicle brakes, which is stored separately in a battery. In some other vehicles, especially trains, the current is fed back into the traction motor.