![]() 12 Apr 2025

12 Apr 2025

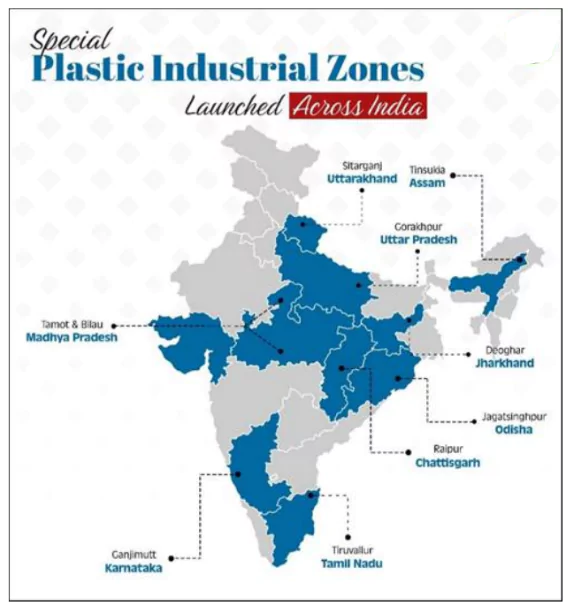

The Department of Chemicals and Petro-Chemicals is implementing the Plastic Parks Scheme under the New Scheme of Petrochemicals.

Stages of Plastic Production

|

|---|

Approved Parks: 10 Plastic Parks have been approved across various states.

Approved Parks: 10 Plastic Parks have been approved across various states.<div class="new-fform">

</div>