Context:

Recently, the Union Minister for Steel and Civil Aviation inaugurated India’s first Green Hydrogen Plant in the Stainless Steel Sector at Jindal Stainless Limited (JSL), Hisar, Haryana.

- The green hydrogen will be used by JSL in stainless steel manufacturing processes at the Hisar unit.

- India’s progress in the steel sector, evolving from a net importer to a net exporter and aiming to become the world’s largest producer of crude steel was highlighted.

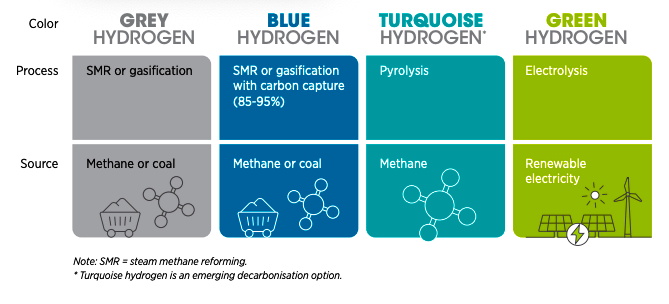

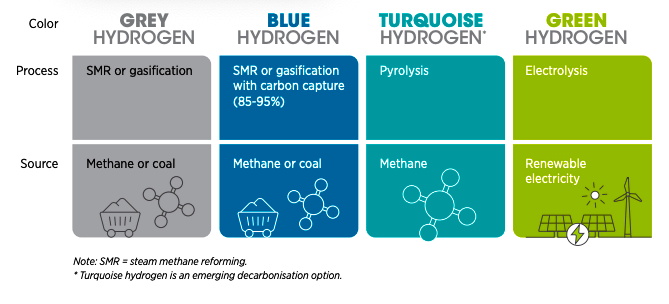

What is Green Hydrogen?

Green Hydrogen is produced using electrolysis of water with electricity generated by renewable energy.

About First Green Hydrogen Plant in India

- It will be the world’s first green hydrogen plant with rooftop & floating solar equipment.

- Aim: To reduce carbon emissions by around 2,700 metric tonnes per annum and 54,000 tonnes of CO2 emission over 20 years.

- Location: Hisar, Haryana.

- Collaboration: between Jindal Stainless Ltd and Hygenco.

- BOO Model: Hygenco is operating the plant under the Build-Own-Operate (BOO) model.

Build Own Operate (BOO): It is a Public Private Partnership (PPP) model for private investment in infrastructure projects

- Ownership of the newly built facility rests with the private party.

- On mutually agreed terms and conditions, the public sector partner agrees to ‘purchase’ the goods and services produced by the project.

|

-

- Decarbonization in Steel Production: Green hydrogen serves as a cleaner alternative to traditional methods.

- Reducing Carbon Emissions: Reduce the carbon footprint but also diversify the energy mix and enhance energy security.

Green Hydrogen can reduce carbon emissions in blast furnaces by almost 20%.

- Enhanced Energy Efficiency: can revolutionise the steel sector in India and set a benchmark for sustainable practices across the globe.

- Green Jobs: It will promote “green growth” and “green jobs” to achieve the target of net zero carbon emission by 2070.

Also Read: National Green Hydrogen Mission

News Source: AIR

![]() 5 Mar 2024

5 Mar 2024