![]() 3 Apr 2024

3 Apr 2024

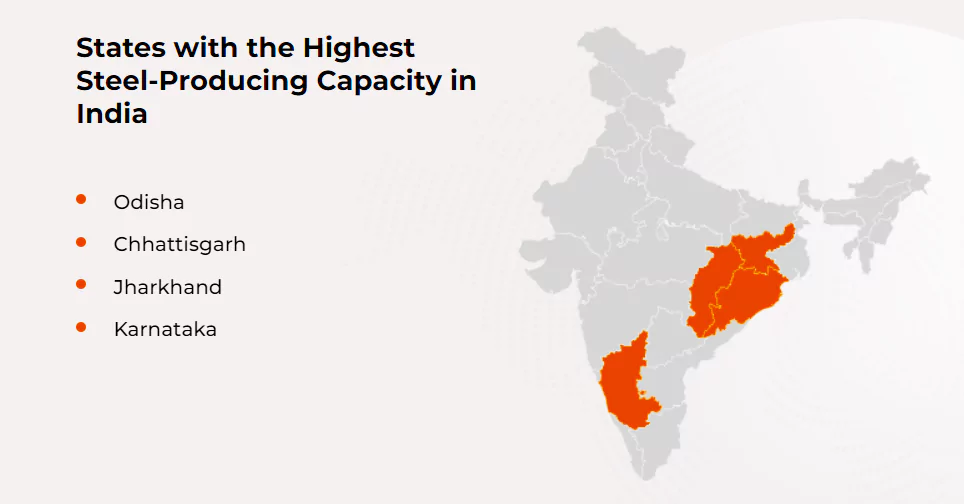

The Steel Ministry has initiated efforts to develop a thorough green steel policy to reduce carbon emissions.

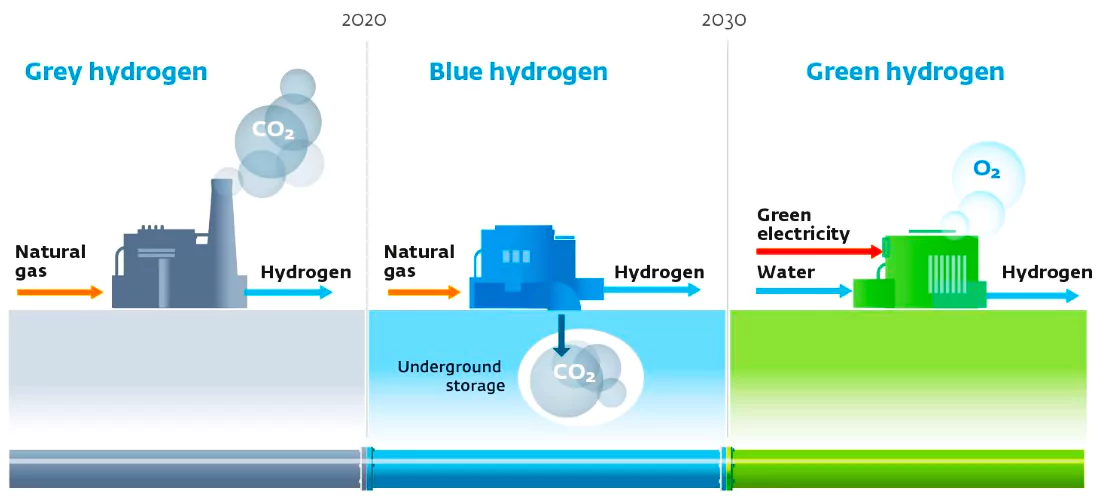

Green Hydrogen: Green hydrogen is a solution that emits only water when it’s burned.

Green Hydrogen: Green hydrogen is a solution that emits only water when it’s burned.| Benefits | Drawbacks |

|

|

Finished steel production stood at 121.29 MT during the same period.

Finished steel production stood at 121.29 MT during the same period.

| Must Read | |

| NCERT Notes For UPSC | UPSC Daily Current Affairs |

| UPSC Blogs | UPSC Daily Editorials |

| Daily Current Affairs Quiz | Daily Main Answer Writing |

| UPSC Mains Previous Year Papers | UPSC Test Series 2024 |

<div class="new-fform">

</div>