Context

India is witnessing an unprecedented construction boom, with over 3,00,000 housing units manufactured annually that poses significant environmental challenges.

Sustainable Construction Materials: Balancing Economic Growth with Environmental Sustainability

- High Energy User Sector: The building sector, a major energy consumer, accounts for over 33% of India’s electricity usage, contributing to environmental degradation and climate change.

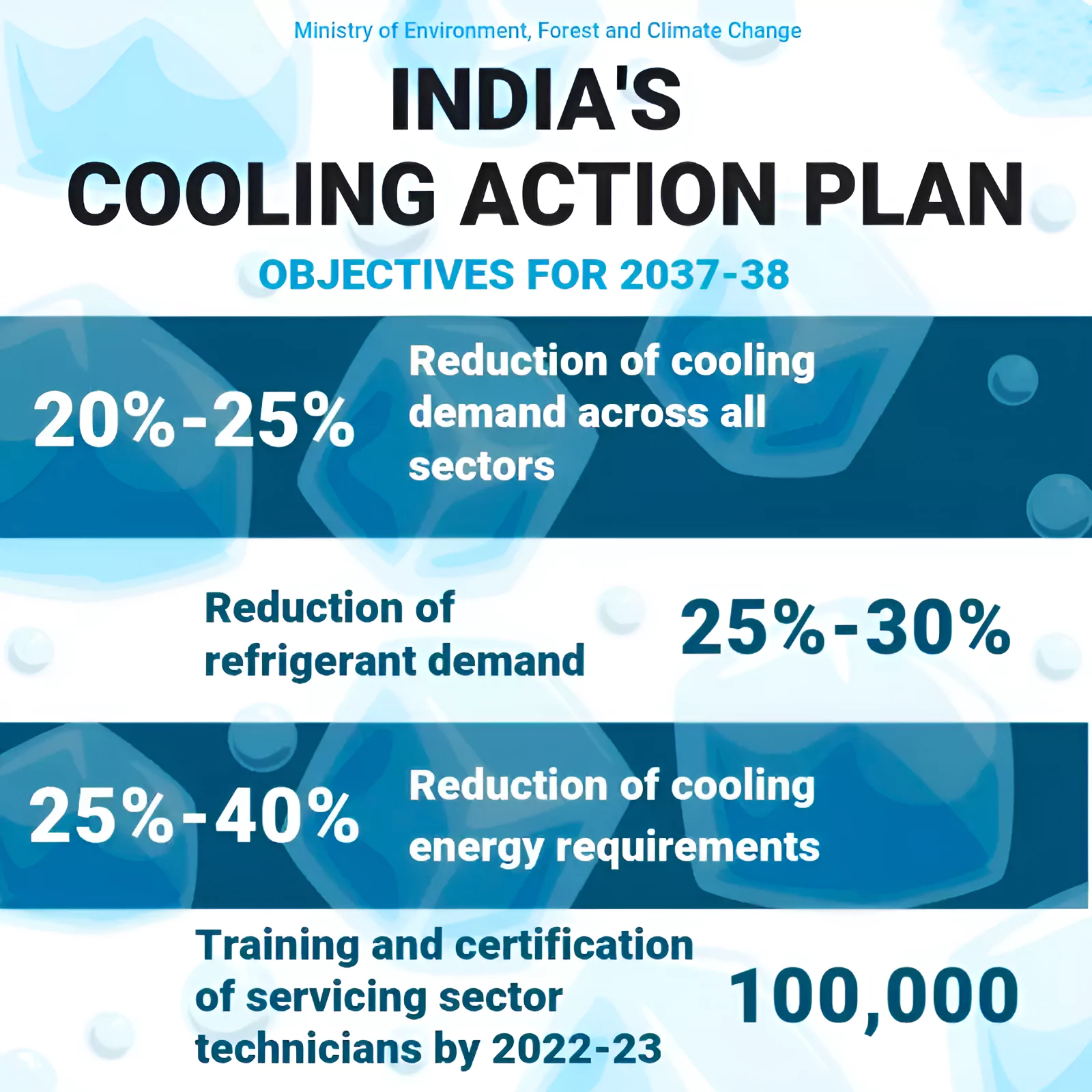

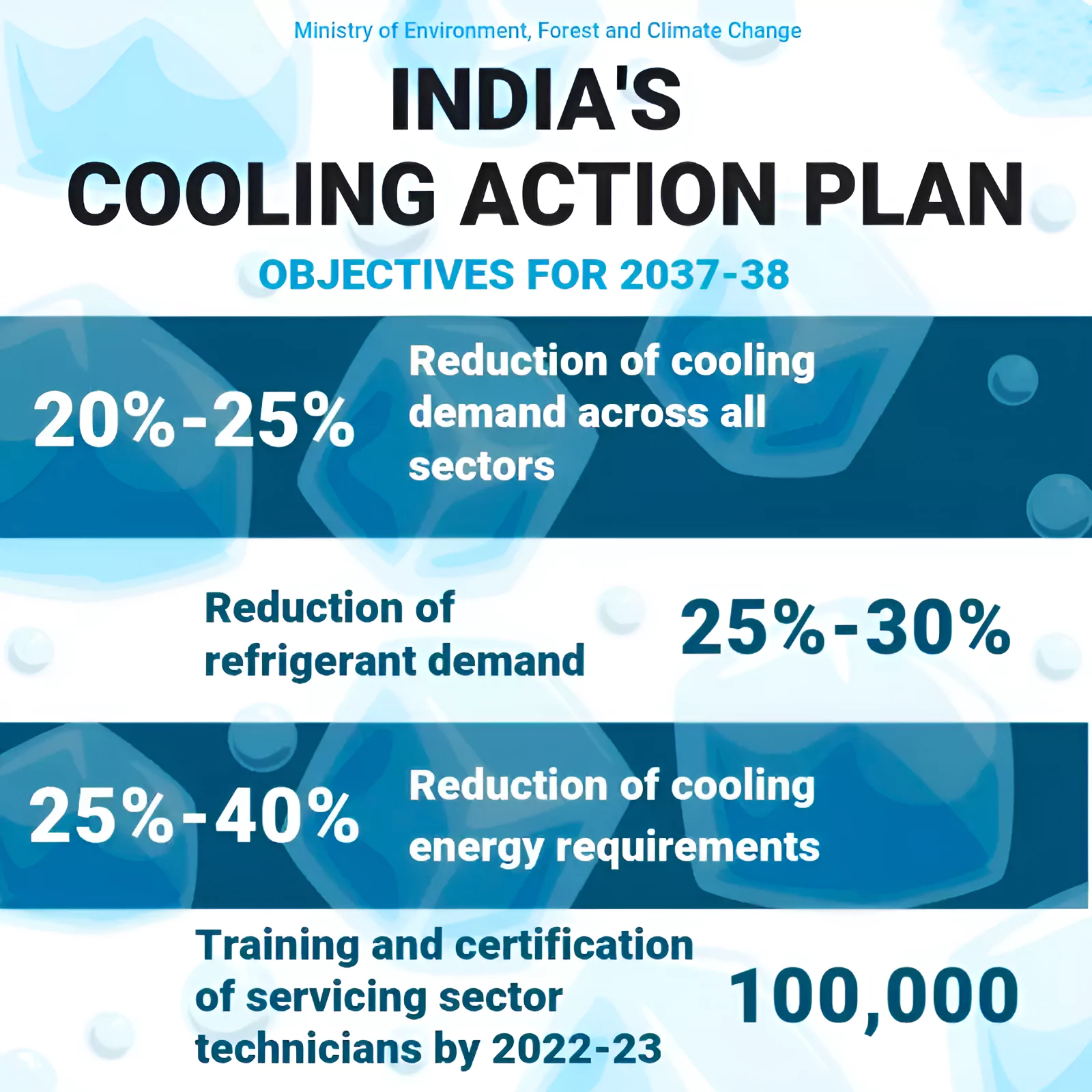

- Increasing Demand: Also, the India Cooling Action Plan (ICAP) forecasts an eight-fold increase in cooling demand between 2017 and 2037, emphasizing the need for thermal comfort while reducing active cooling demand.

Initiatives taken by the Government for Energy-Efficient Construction Sector

- The Eco Niwas Samhita (ENS) and the Residential Energy Conservation Building Code.

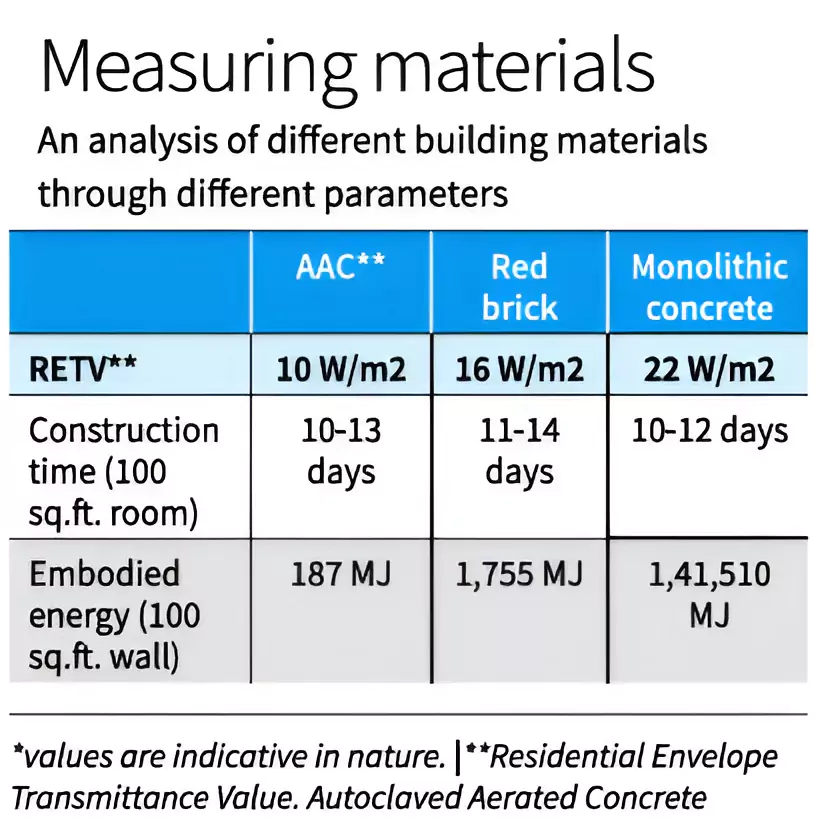

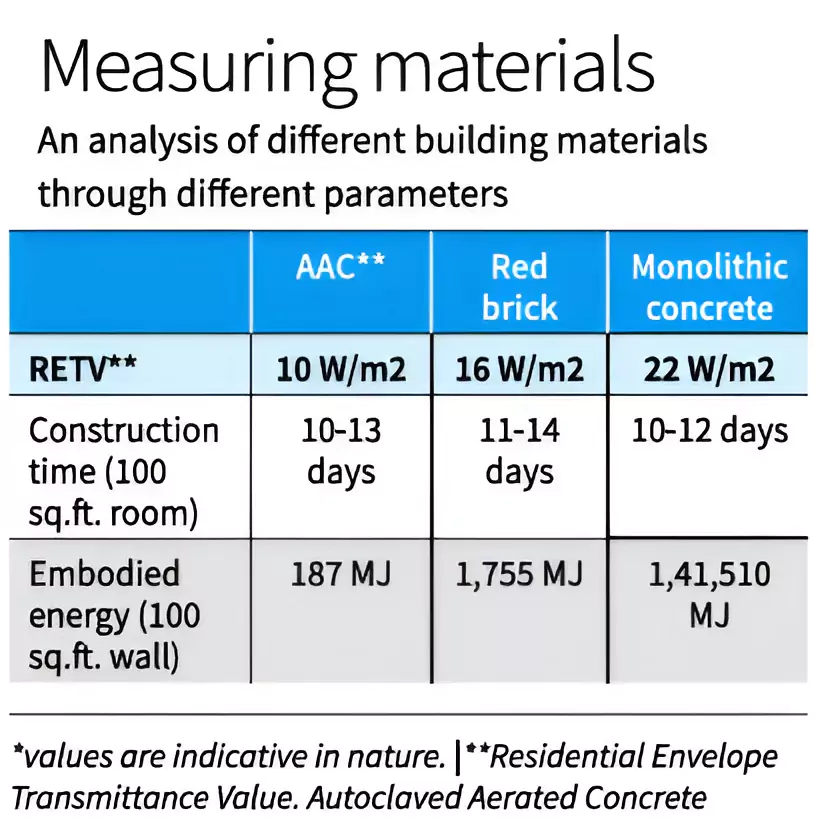

- The ENS introduces the Residential Envelope Transmittance Value (RETV), a metric measuring heat transfer through a building’s envelope.

- Lower RETV values lead to cooler indoor environments and decreased energy usage.

- For optimal efficiency, improved occupant comfort, and lower utility expenses, an RETV of 15W/m2 or less is recommended.

Optimal Construction Materials

- Autoclaved Aerated Concrete or AAC Blocks

- Red Bricks

- Fly Ash

- Monolithic Concrete (Mivan)

RETV Evaluation for the Construction Materials

- Autoclaved Aerated Concrete or AAC Blocks: They consistently had the lowest RETV across all climatic conditions, indicating their potential as a thermally efficient material. They have lower embodied energy compared to monolithic concrete and red bricks, while still contributing to emissions and waste.

- AAC blocks offer a better balance between embodied energy and construction time than red bricks and monolithic concrete.

- Embodied energy is the energy associated with the manufacturing of a product.

- Monolithic Concrete (Mivan): Despite its quick construction time, it presents the highest embodied energy (an embodied energy 75 times greater than AAC blocks), significant environmental impact, and sustainability challenges.

- Despite concerns about sustainability, it was favored by building developers for its speed, strength, quality, and scalability.

- Over 60% of buildings under design and construction phases opt for it, especially in high-rise buildings and skyscrapers.

- It offered faster construction of buildings compared to traditional masonry work, particularly for taller structures.

- Red Bricks: For estimated construction time for a 100 sq. ft room, red bricks required the longest time.

- They exhibit moderate embodied energy, contributing to resource depletion, emissions, and waste.

Way Forward

- Interdisciplinary Collaborations: Collaborations with sustainability experts is a need to unlock the potential for a sustainable built environment.

- Example: For integrated design and optimise strategies like building orientation, Window Wall Ratio (WWR), U-value (rate of heat transfer) of walls, roofs and window assemblies, glazing performance, active cooling systems, etc.

- Innovation: Sustainable construction requires innovation from building materials manufacturers to develop cost-effective, scalable, durable, fire-resistant solutions with superior thermal performance and climate resilience.

- Knowledge and Awareness: There is a need to have more widespread knowledge about climate-appropriate design and architecture.

Conclusion

The journey toward sustainable construction is challenging but essential for a greener future. The goal can be achieved by re-imagining construction design and practices, manufacturing innovative walling materials, and fostering a culture of sustainability, resilient and energy-efficient structures that align with environmental goals and significantly improve the quality of life for the masses.

Also Read: Rejupave Technology In Road Construction

![]() 30 Mar 2024

30 Mar 2024