Context:

This article is based on the news “Union Cabinet approves Rs 8,500 cr incentive for coal gasification projects” which was published in the Business Standards. Recently, The Union Cabinet approved a viability gap funding (VGF) scheme of ₹8,500 crore for coal gasification projects for public and private sector companies.

Govt Approves Rs 8500 Cr for Coal Gasification Projects

- VGF to three Categories of Projects:

- First category: Under this, a provision of Rs 4,050 crore has been made for Public Sector Utilities (PSUs), supporting up to three projects.

- This support will be extended through a lump sum grant of Rs 1,350 crore or 15% of the capital expenditure, whichever is lower.

- Second category: Under this, Rs 3,850 crore has been allocated for both government and private sector projects.

- Each project in this category will receive a lump sum grant of Rs 1,000 crore or 15% of the capital expenditure, whichever is lower.

- Third Category: Under this, Rs 600 crore has been provisioned for demonstration projects (indigenous technology) or small-scale product-based gasification plants.

- A lump-sum grant of Rs 100 crore or 15 per cent of capex, whichever is lower, will be given to the selected entity.

- Selection of Entities: The selection of entities under categories II and III through a competitive and transparent bidding process.

- The grant will be paid to the selected entity in two equal instalments.

- Incentives for Gasification: The government has also offered a 50 per cent rebate in revenue share for the coal used for gasification, provided the quantity used for gasification is at least 10 per cent of the total coal production.

- Approval for Coal Gasification Projects: The Cabinet also approved two coal gasification projects under the scheme where Coal India Limited (CIL) will make equity investments beyond the limit of 30 per cent.

- Mandatory Green clearance: To address environmental concerns in the coal gasification process, the government has mandated a grant of green clearance.

- The project proponent must conduct environmental impact assessment studies and prepare an environment management plan.

- An expert committee will duly examine the plan before taking up any activities related to establishing a coal gasification plant.

What is Coal Gasification?

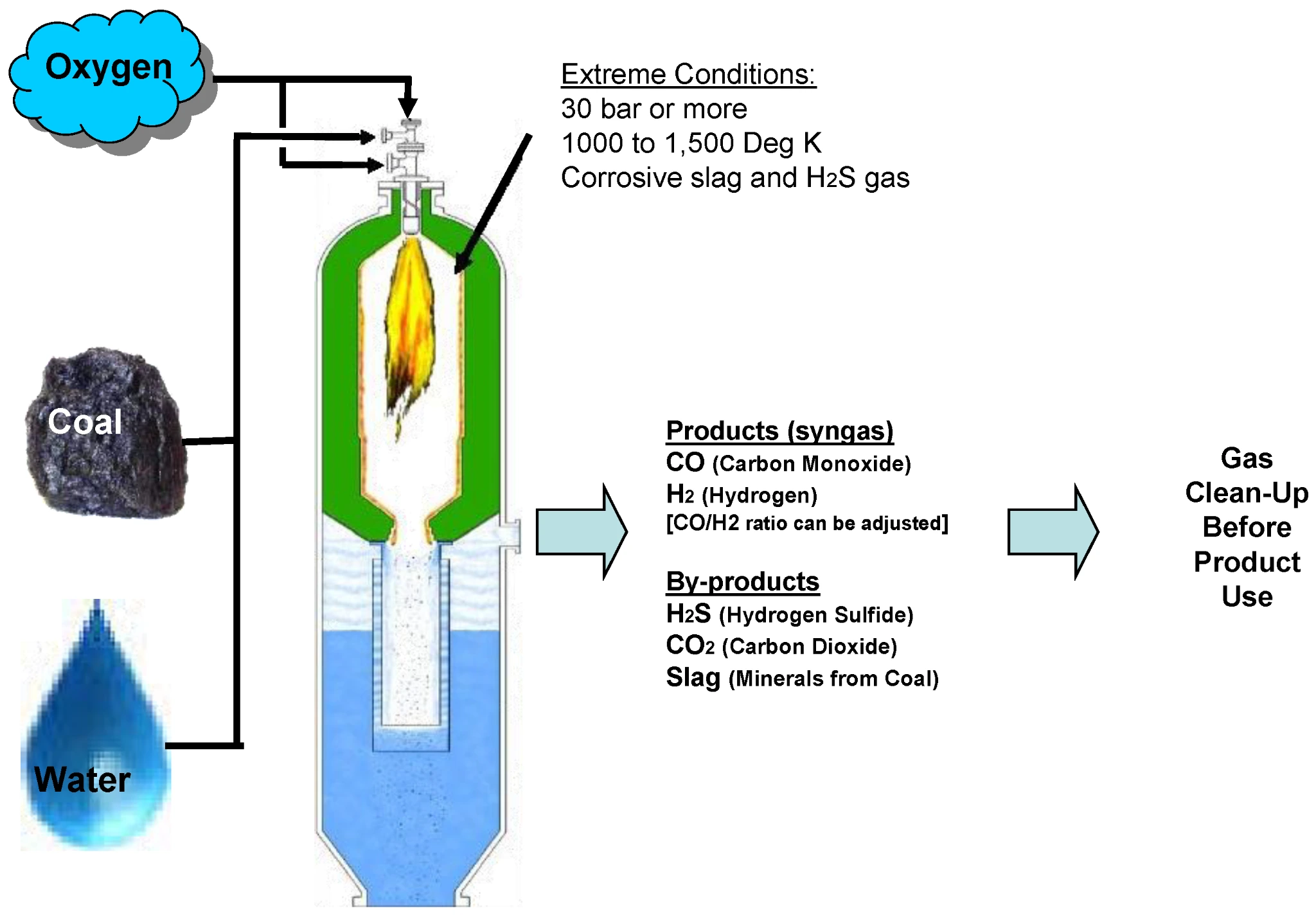

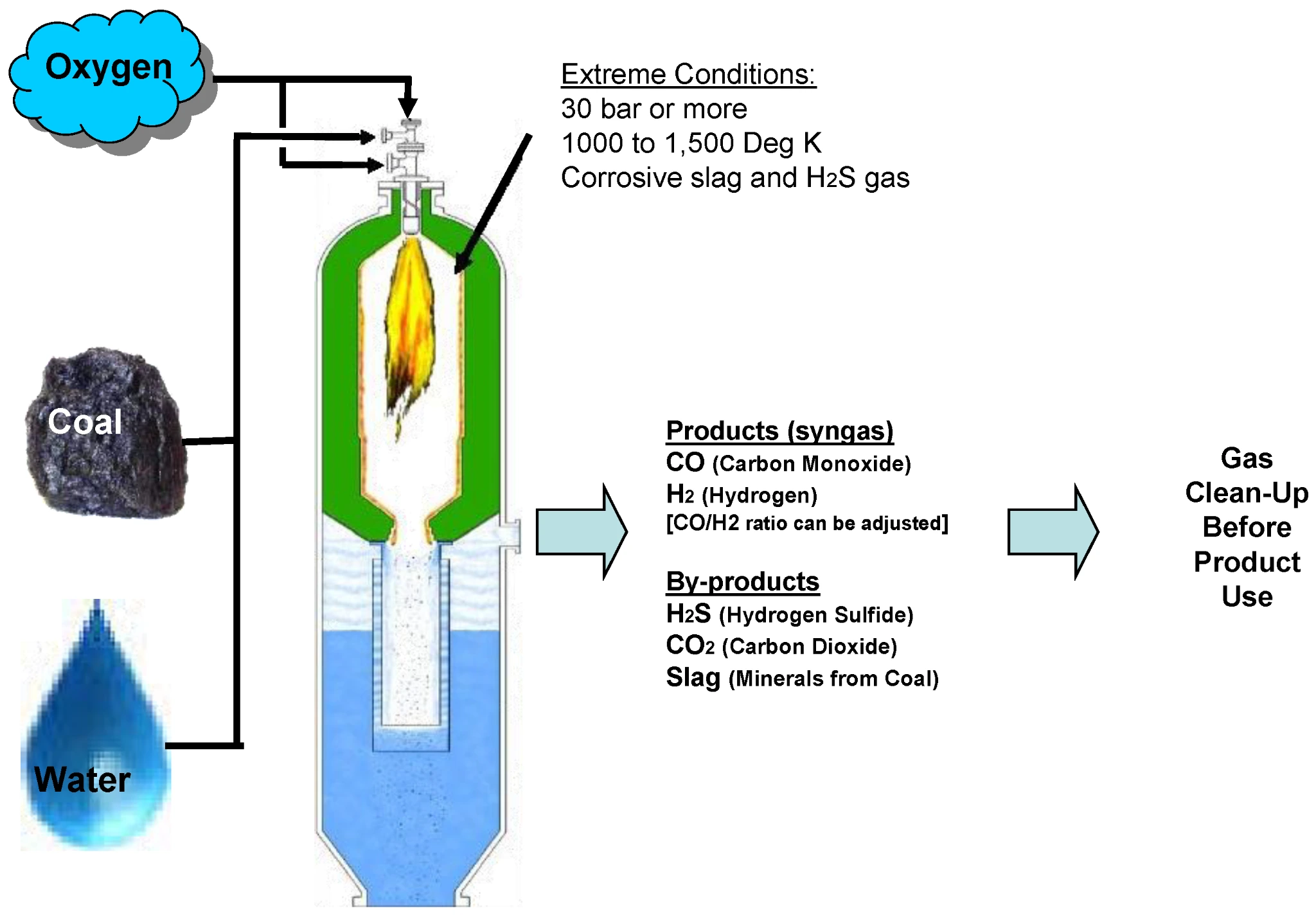

- About: Coal Gasification is a thermo-chemical process that converts coal into simple molecules, primarily carbon monoxide and hydrogen, called synthesis gas or syngas.

- Mechanism: In the gasification process, coal is partially oxidised by air, oxygen, steam, or carbon dioxide under controlled conditions to produce a liquid fuel known as syngas.

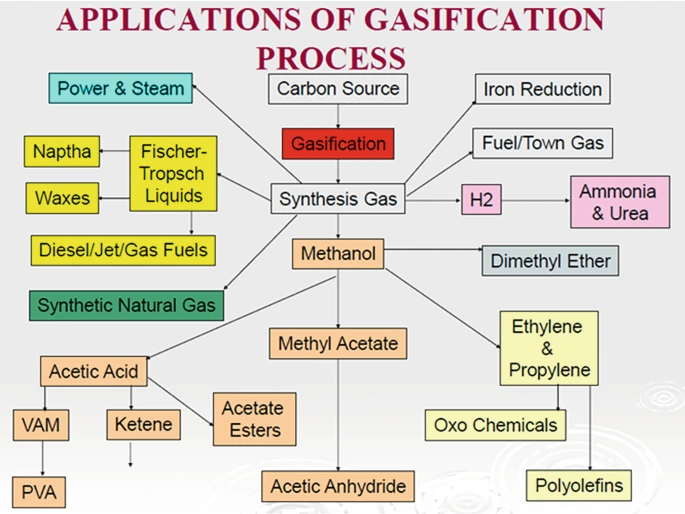

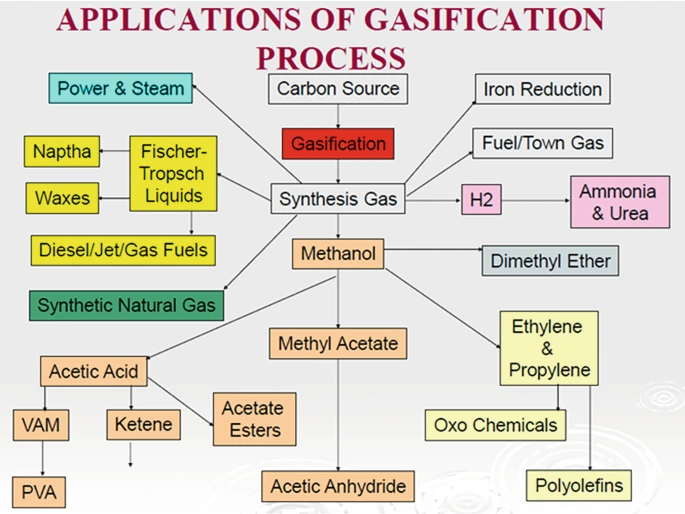

- Syngas or synthesis gas can be used to generate power and make methanol.

- Significance: The combustion of this gas is cleaner and more efficient than coal combustion since emissions are trapped at the gasification stage.

Methods of Coal Gasification

- In-situ method: In this, oxygen is infused into the seam together with water and ignited at high temperatures, causing coal to partly oxidize into hydrogen, CO, carbon dioxide (CO2), methane (CH4), and hydrogen sulfide (H2S).

- Ex-situ reactors: They are designed to simulate the gasification process above the ground’s surface.

- Sulphur in coal is transformed to H2S and trace volumes of carbonyl sulphide (COS) during the gasification process.

Also Read: Methane Alert And Response System (MARS)

Need for Coal Gasification

- A Proven Reserve of Thermal Coal: A country’s total estimated coal reserve (resource) per the Coal Inventory published by GSI, as of 01.04.2022 is 361411.46 million tonnes”.

- Global Standing: Second largest in the world after China.

- Production Surge: 14.8 % rise in production reaching 893 MT in the 2022–2023 financial year.

- Contribution: India contributes more than 10% of the global coal production.

- Coal Gasification Target: The government has launched the National Coal Gasification Mission to achieve coal gasification and liquefaction of 100 MT of coal by 2030.

- Government Production Target:

- The Government aims for self-reliance by boosting domestic production.

- Targeting over 1 billion tonnes in 2023–2024 and further increase it to 1.5 billion tonnes by 2029–2030.

- Reducing Import Dependency: India has a huge dependency on imports of crude and natural gas-based products mainly methanol, ammonia, ammonium nitrate, and olefins, which can be easily substituted by by-products derived from syngas.

- It can yield methanol blended with petrol, Di-Methyl Ether (DME) to be blended with LPG to substitute imported coking coal in blast furnaces and produce synthetic natural gas (SNG).

- At present, India imports about 50% of its Natural Gas, more than 90 per cent of its methanol consumption and 13-15 per cent of its domestic ammonia requirement.

- Transition to Sustainable Energy: India has huge reserves of coal, it would benefit India if it finds a sustainable way of using these reserves as the world including India is gradually transitioning away from coal toward cleaner fuels in the wake of climate change.

- India has an estimated coal reserves of 361 billion tonnes, the fourth largest in the world and enough to last more than a century.

- Sustainable Usage of Coal: Given India’s growth potential and rising demand for power, the demand for coal is projected to rise from the current requirement of nearly one billion tonnes to 1.5 billion tonnes by 2029-30.

- To encourage greener use of coal, the government is promoting more sustainable practices such as coal gasification, which involves turning coal into cleaner fuel gas.

Pharmaceutical Industry: India plans to produce active pharmaceutical ingredients (API) domestically rather than importing them from China.

Pharmaceutical Industry: India plans to produce active pharmaceutical ingredients (API) domestically rather than importing them from China. -

- There is a high potential for Syngas to make APIs and methanol as a solvent.

- Cleaner and environmentally Friendly: Coal gasification plants produce no scrubber sludge.

- The majority of the wash water is reprocessed, and residual wastewater from gasification plants can be treated effectively.

- As a result, coal gasification is considered a cleaner coal technology than coal combustion.

Coal Gasification in India: Challenges

- Inferior Quality of Coal: The high ash content in Indian coal is a technical barrier to a larger adoption of coal gasification.

- The ash percentage of indigenously available coal ranges between 30-35 per cent even after washing, which is quite high.

- Reaching ash content below 30% is not economical and feasible even after washing. Despite government directives to wash coal down to 34% ash, compliance is very low and presents structural challenges.

- Induced Subsidence of Surrounding Rocks: The space created by deep mining during the coal gasification may cause significant deformation in the remaining coal and surrounding rocks.

-

- Heating, quenching, water flux and potential roof and wall collapse may seriously compromise the integrity of the cavity, leading to a subsidence.

- Occupational Hazard: The coal Gasification process cannot be controlled to the same extent as surface gasifiers, which poses the risk of high temperature and pressure in the cavity, furthering the workers’ risk.

- Environmental Factors: According to some studies, coal gasification generates more CO2 than a conventional coal power station.

- Groundwater Contamination: While the nation already faces water scarcity, coal gasification is a more water-intensive energy generation method.

- Economy of Project: It is an inherently ‘unsteady’ state process; the flow rate and the heating value of the product gas will vary over time.

- Changes in the quantity and quality of gas produced will significantly impact the project’s economics.

- Technological Concern: Lack of availability of proven gasification technology suitable for poor poor-quality Coal.

Way Forward to the Coal Gasification

- Regulation on Ash Content: The ash content of coal supplies needs to be enforced. Present regulations limiting ash content to 34% are not being enforced.

- Coal washeries pose challenges regarding investment, water usage and water disposal.

- Coal blending is the path forward, as waste streams from the gasification process are easier to handle and can be value-adding in themselves (e.g. sulphur, slag)

- Dedicated Closed Coal Mines for Coal Gasification: Coal Mines should be earmarked for Coal Gasification Projects (to be awarded through Auction Linkage) for better Coal Quality consistency, sustained Supply & closer Mining & Transportation Cost control.

- Viability Gap Funding: Financial incentives from the government to support very high CAP of gasification projects needed to improve the viability of ‘Energy Security’ (Clean) projects.

- The Viability Gap Funding (VGF) aims at supporting infrastructure projects that are economically justified but fall marginally short of financial viability

- Level Playing Field: Exemption from currently applicable Cess / Duties on Coal Feedstock prices should be provided for environment–friendly Coal Gasification Projects due to its Clean Technology adaptation.

- National Policy on Coal Gasification & Liquefaction: This should be urgently formulated and promulgated for faster and smoother implementation of Coal Gasification Projects.

- Blending Schemes and Policy Framework: Schemes for ‘Blending Methanol, DME with Gasoline & LPG’ should be implemented as soon as possible, along with a policy framework for all by-products of coal gasification.

- Leveraging Global Gasification Technologies: India should leverage the gasification technology globally available for fast-track development of local coal for the chemical industry.

Conclusion

The deployment of coal gasification will support India’s ‘Aatmanirbhar‘ vision, stimulate job creation and significantly reduce imports by 2030. Moreover, it presents a solution for environmental concerns, promising to lower carbon emissions and promote sustainable practices, aligning with worldwide commitments towards a greener future.

Also Read: National Coal Index

![]() 25 Jan 2024

25 Jan 2024

Pharmaceutical Industry: India plans to produce active pharmaceutical ingredients (API) domestically rather than importing them from China.

Pharmaceutical Industry: India plans to produce active pharmaceutical ingredients (API) domestically rather than importing them from China.