![]() 1 Feb 2024

1 Feb 2024

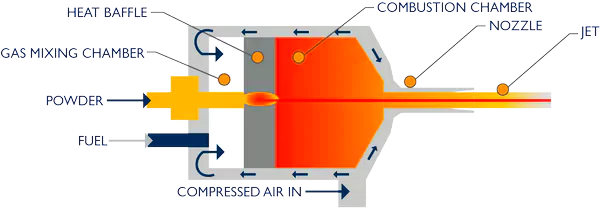

Indian scientists claim to have discovered High Velocity Air Fuel (HVAF) Spray Technique as an alternative to hard chrome plating.

Chrome Plating

|

|---|

News Source: PIB

| Must Read | |

| NCERT Notes For UPSC | UPSC Daily Current Affairs |

| UPSC Blogs | UPSC Daily Editorials |

| Daily Current Affairs Quiz | Daily Main Answer Writing |

| UPSC Mains Previous Year Papers | UPSC Test Series 2024 |

<div class="new-fform">

</div>