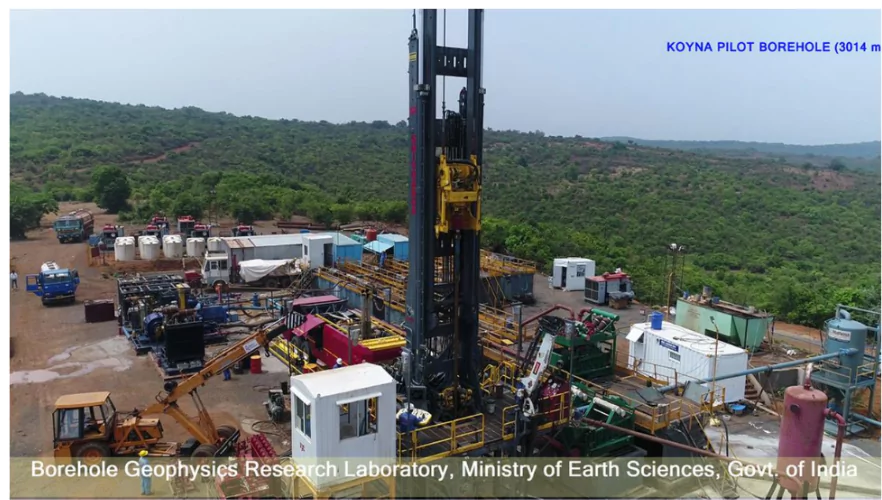

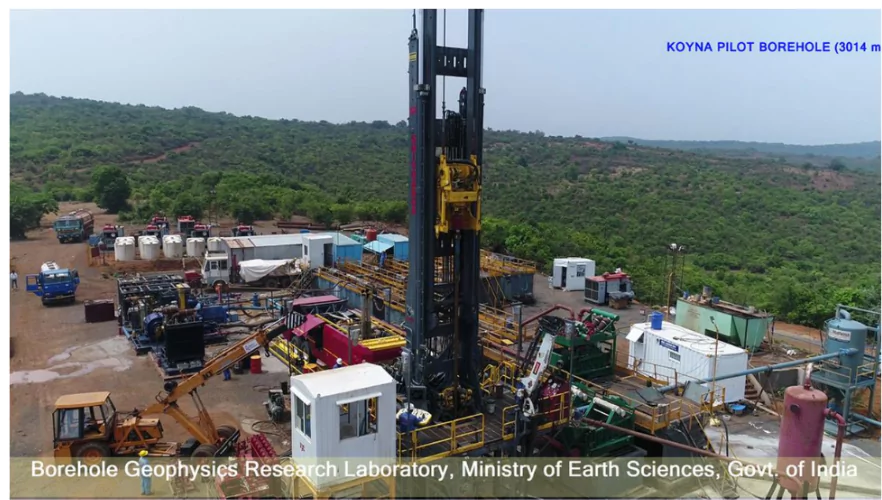

The Borehole Geophysics Research Laboratory (BGRL)’s pilot borehole to a depth of 3 km in Koyna, Maharashtra has been completed.

- This region has been experiencing frequent and recurrent earthquakes since the Shivaji Sagar Lake, or the Koyna Dam, was impounded in 1962.

About Scientific Deep Drilling

Scientific deep drilling is an indispensable tool for progress in the earth sciences.

- Refers: It is the enterprise of strategically digging boreholes to observe and analyze deeper parts of the earth’s crust.

- Need: It offers opportunities and access to study earthquakes and expands the understanding of the planet’s history, rock types, energy resources, life forms, climate change patterns, the evolution of life, and more.

- Also, earthquakes, many surface phenomena — the composition of water and air, their availability, and the resulting interactions with climate-affected phenomena — are linked to what happens inside the earth’s crust.

Enroll now for UPSC Online Course

Importance of Deep Drilling Mission

It has many significance for which many countries like the U.S., Russia, and Germany conducted such scientific projects in the 1990s. Recently, in 2023, there were reports of China undertaking a deep-drilling mission of its own.

- Widen the Understanding for Earthquakes: Scientific deep-drilling remains the most reliable method as they can be a hub of direct, in-situ experiments and observations and strategically monitor a region’s fault lines and earthquake behavior (including nucleation, rupture, and arrest).

- It offers a unique opportunity to widen the understanding of earthquakes and to use the resulting knowledge for scientific and public good.

- Scientifically drilled boreholes to great depths can be thought of as downward-looking telescopes, which when instrumented with sensors serve as geological observatories.

- Widening of Knowledge and Understanding: It also provides exact, fundamental, and globally significant knowledge of the composition of the earth’s crust, structure, and processes, and helps confirm or reject models based on surface studies.

- It can provide information to inform a range of societal problems related to geohazards and geo-resources in India.

- Opportunity to be Self-Reliant: Investing in scientific deep-drilling can also help expand scientific know-how and technological innovation, especially in seismology (the study of earthquakes).

- It can also promote the development of tools and equipment for drilling, observation, data analysis, sensors, etc., another front on which India has the opportunity to be self-reliant.

Challenges with Deep Drilling Missions

Scientific deep-drilling is also the most challenging method:

- It is labor- and capital-intensive.

- The earth’s interior is also a hot, dark, high-pressure region that hinders long and continuous operations

India’s Deep Drilling Mission

The BGRL in Karad, Maharashtra, is a specialized institute under the Ministry of Earth Sciences of the Government of India mandated to execute India’s sole scientific deep-drilling programme.

- Aim: To drill the earth’s crust to a depth of 6 km and conduct scientific observations and analysis to help expand the understanding of reservoir-triggered earthquakes in the active fault zone in the Koyna-Warna region of Maharashtra.

- Drilling Technique at Koyna: The Koyna pilot borehole is about 0.45 m wide (at the surface) and roughly 3 km deep. A hybrid of two well-established techniques called mud rotary drilling and percussion drilling (a.k.a. air hammering).

Check Out UPSC CSE Books From PW Store

About Mud Rotary Drilling

- Comprises:

- A rotating drilling rod made of steel, attached to a diamond-embedded drill bit at the bottom.

- An annular (ring-shaped) space separates the drilling rod and borehole wall.

- Working:

- As it cuts the rocks and penetrates the crust, it generates a lot of heat due to friction, so a cooling liquid or drilling mud is flushed through the drilling rod into the borehole to cool the drill bit.

- In addition to working as a coolant and a lubricant, the drilling mud also helps bring up the debris or rock cuttings from the borehole.

- The debris moves out from the annular ring space due to the pressure of the drilling mud pumped from the top through the drilling rod.

- The deeper the borehole, the more pressure is required to bring up the debris from the annular space.

About Air Hammering

- It pushes highly compressed air (in place of the drilling mud) through the drilling rod to deepen the borehole and flush the cuttings out.

Decision to use Each Technique

- Decisions of this kind are dynamic and require meticulous planning and drilling acumen. It is based on the site’s requirements, such as rock type, presence of highly fractured rock, water inflow zones, and the need to collect core samples, among others.

- Mud Rotary Technique: To acquire a sample of the core, as this mud rotary technique allows to capture long, intact cylindrical cores.

- Air-Hammering Technique: It is used in those regions where the team collected rock chips scientists use for various studies of rock properties.

|

Challenges of Hybrid Technique

The hybrid technique has several challenges.

- Hook Load Capacity: The load on the rig’s hook keeps increasing as the borehole gets deeper and with the addition of new drilling rods and steel casing pipes. Also with increasing depth, the required compressed air pressure to lift the drill cuttings increases manifold.

- Example: For the operations at Koyna, operators deployed a rig with a hook load capacity of 100 tonnes and casing down to a depth of 3 km.

- Complexities: When the borehole depth increases beyond 3 km and strikes for 6 km, the entire rig will have to be updated with exponentially enhanced capacity.

- Operators will also encounter more frequent fault lines and fracture zones, through which water could enter the borehole and stall the drilling exercise.

- Need for Special Equipment: To steer the borehole at the desired inclination from the top, using vertically controlled actions requires special equipment like drill motors, imaging tools, and monitoring devices that can be ‘tuned’ every minute.

- The planning and execution of deep-drilling are thus dynamic and must be meticulous and foolproof.

- Human Resources: The process needs highly skilled and trained technical personnel for a 24/7 on-site engagement.

- For a 3 km borehole, 24/7 drilling will last for at least 6-8 months.

- For a 6 km borehole, 24/7 drilling will last for at least 12-14 months.

Achievements So Far

The pilot drilling mission was a success and has yielded significant new information:

- Nature of Region: It revealed that Koyna region is critically stressed, so even small stress perturbations could cause the rock to fail and potentially trigger frequent, small-magnitude earthquakes in the region.

Presence of Water down to 3 km: It was found to be meteoric or rain-fed, implying deep percolation and circulation are possible.

Presence of Water down to 3 km: It was found to be meteoric or rain-fed, implying deep percolation and circulation are possible. - New Insights to Reservoir-triggered Earthquake Mechanisms: It revealed 1.2-km thick and 65 million-year-old Deccan trap lava flows, and below them 2,500-2,700-million-year-old granitic basement rocks.

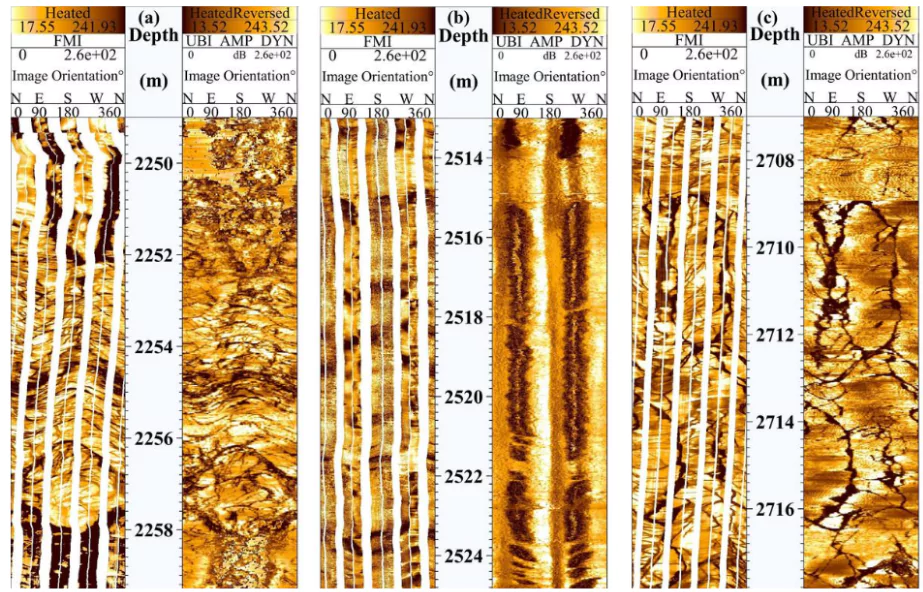

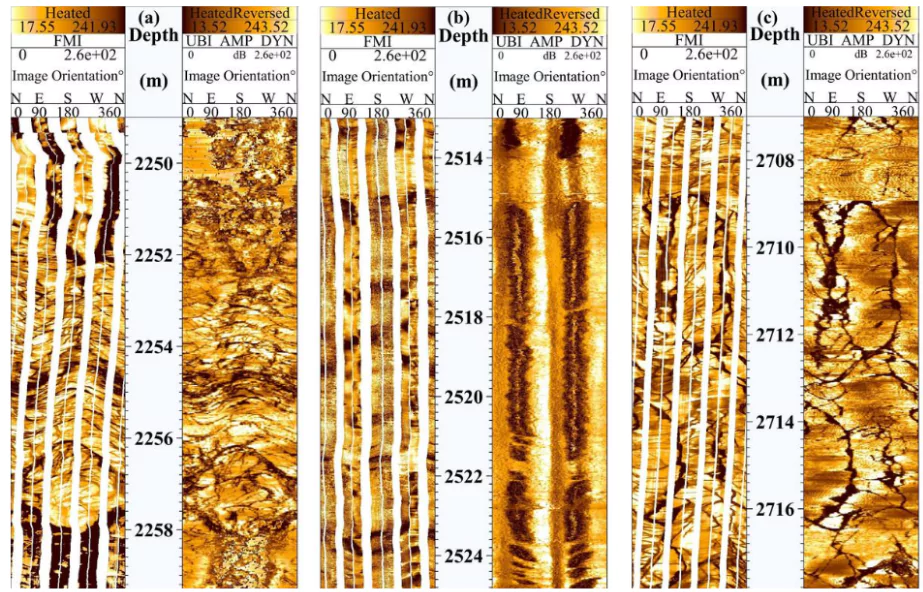

- Revealed Information on Rocks: Core samples and conditions from a depth of 3 km have provided hitherto unknown information on the physical and mechanical properties of rocks, the chemical and isotopic composition of formation fluids and gases, temperature and stress regimes, and fracture orientations at depth.

- Validation of Data: Captures of high-resolution images of the borehole wall using acoustic and micro-resistivity techniques provide an opportunity for scientists worldwide to validate or corroborate data extracted from other cores.

- The team at Koyna also conducted hydraulic fracturing experiments to measure the in-situ stress regime of the rocks. By integrating various datasets and using advanced analysis, the team could also detect buried fault zones and study their properties.

Enroll now for UPSC Online Classes

Conclusion

The Koyna data and samples will also facilitate new experiments and is establishing a firm footing in scientific deep-drilling for India. Its lessons will inform future deep-drilling experiments as well as expand academic knowledge in multiple ways.

- Modelling experiments have revealed the expected temperature at 6 km could be 110-130 degrees C. Therefore, drilling equipment, downhole data acquisition systems, and sensors for long-term placement at depth need to be designed accordingly.

![]() 11 Jul 2024

11 Jul 2024

Presence of Water down to 3 km: It was found to be meteoric or rain-fed, implying deep percolation and circulation are possible.

Presence of Water down to 3 km: It was found to be meteoric or rain-fed, implying deep percolation and circulation are possible.