Ministry of Coal has initiated India’s first-ever pilot project for Underground Coal Gasification (UCG) at the Kasta coal block in Jamtara District, Jharkhand.

- The initiative is under the aegis of Eastern Coalfields Limited (ECL) and aims to revolutionize the coal industry by converting coal into valuable gasses such as methane, hydrogen, carbon monoxide, and carbon dioxide through in-situ gasification.

More on News

Methods of Coal Gasification

- In-Situ Coal Gasification/Underground Coal Gasification (Ucg) – is the technique of converting coal into gas while it is still in the seam and then extracting it through wells.

- UCG provides a crucial benefit by unlocking coal deposits that are not economically feasible to extract using conventional mining techniques.

- Ex-Situ Coal Gasification: It is designed to simulate the gasification process above the ground surface, where Sulphur in coal is transformed to H2S and trace volumes of carbonyl sulphide (COS).

|

Initiative Comprises Two Phases

- Initial phase: It involved creating a technical feasibility report through drilling boreholes and testing core samples.

- Second phase: It will focus on pilot-scale coal gasification.

- Benefits: Expected to open transformative opportunities for India’s energy sector, demonstrating the sustainable and efficient use of the nation’s coal resources.

Enroll now for UPSC Online Course

What is Coal Gasification?

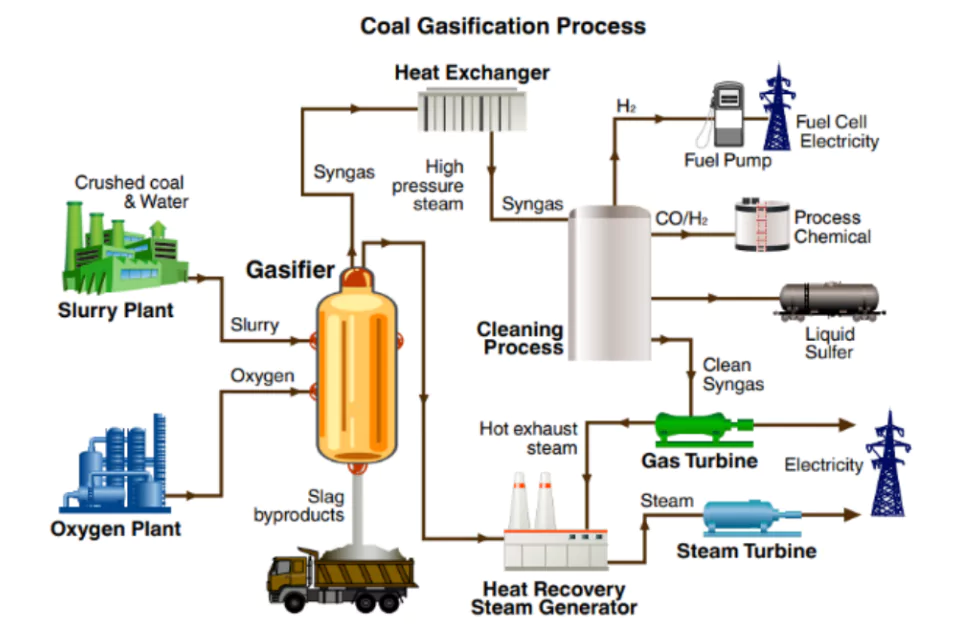

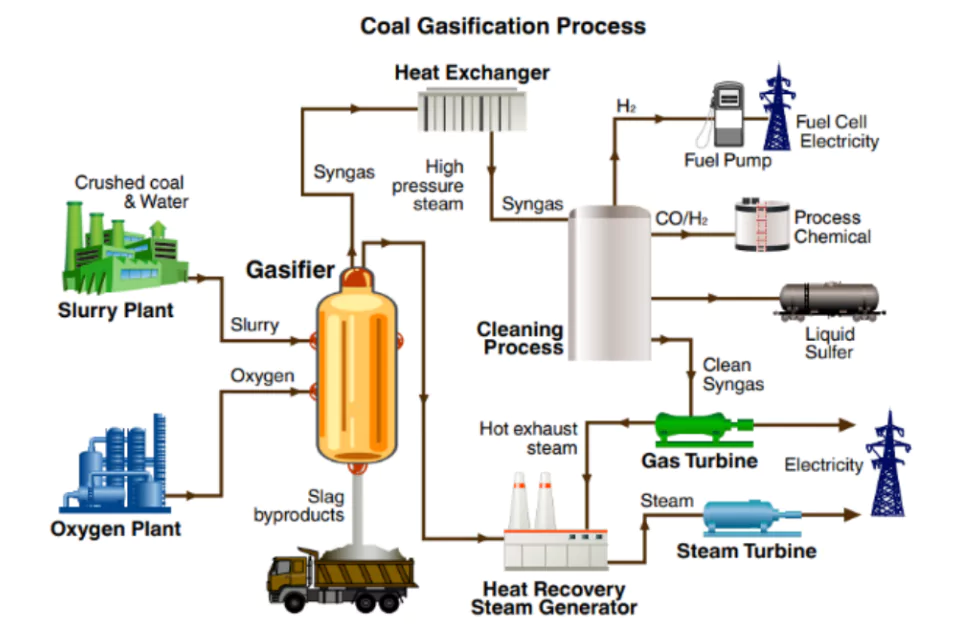

- About: A thermo-chemical process that converts coal into simple molecules, primarily carbon monoxide and hydrogen, called synthesis gas or syngas.

- Mechanism: In the gasification process, coal is partially oxidised by air, oxygen, steam, or carbon dioxide under controlled conditions to produce a liquid fuel known as syngas.

- Significance: The combustion of this gas is cleaner and more efficient than coal combustion since emissions are trapped at the gasification stage.

Image Source: White Paper on Coal Gasification

Advantages of Coal Gasification

Following Are The Advantages Of Coal Gasification In The Various Sectors:

- Industrial Application of Coal Gas

-

- Raw Source of Energy: Syngas can be used to generate power, in energy-efficient fuel cell technology, or as chemical “building components” for industrial applications.

- Source of Hydrogen economy: The hydrogen can also be extracted and used to power a hydrogen economy.

- Automobile Fuel: Coal gas can also be transformed into a transportation fuel to be used in automobiles as a replacement for gasoline.

- Steel Industry: Syngas (CO and H2) are essential reducing agents for steel production and are regarded as an environmentally friendly technique of steel production because they reduce the import of furnace oil.

- Generating Electricity: The synthesis gas can be used in an Integrated Gasification Combined Cycle (IGCC) system to generate electricity in an efficient and environmentally friendly manner.

- Green energy production: The hydrogen produced by coal gasification may be utilised for a variety of applications, including the production of ammonia and the powering of a Hydrogen Economy.

- AtmaNirbhar Bharat: The syngas produced by coal gasification can be used to generate urea and a variety of products such as methanol, Dimethyl ether (DME), and olefins, allowing India to minimize imports and become self-sufficient.

- Cleaner and Environmental Friendly: The majority of the wash water is reprocessed, and residual waste waters from gasification plants can be treated effectively.

- Carbon Capture and Storage: another advantage of coal gasification is the fact that it lets you separate the good parts from the bad, and select the parts you want to keep.

- Achieving Paris Commitment: India announced environmental targets as its Nationally Determined Contribution (NDC) under the Paris Agreement in 2016 and revised targets in COP 26 at Glasgow.

- Coal gasification aids in the decrease of emission levels and the advancement of non-fossil fuel-based energy resources.

- Pharmaceutical Industry: India has ambitious plans to produce active pharmaceutical ingredients (API) domestically rather than importing them from China.

-

- There is a high potential of Syngas in making APIs, as well as methanol as a solvent.

Government Initiatives To Promote Coal Gasification

- Union Cabinet approved a viability gap funding (VGF) scheme: an outlay of Rs 8,500 crore as financial assistance for promoting coal, lignite gasification projects.

- Government has also approved setting up of

- Coal-to-SNG (Synthetic Natural Gas) project through a joint venture between Coal India and GAIL

- Coal-to-ammonium nitrate project through a joint venture between CIL and BHEL

- To introduce clean coal technologies: The Government has launched several clean coal initiatives, including the Coal Gasification Mission.

- It aims to gasify 100 million tonnes of coal by 2030 through surface coal/lignite gasification projects.

- Clean coal initiatives: Government is also actively engaged in clean coal initiatives such as extraction of Coal Bed Methane (CBM) gases, exploring Coal to Hydrogen, Carbon Capture and Storage (CCS), Coal beneficiation through washeries, etc. to mitigate emissions and enhance environmental sustainability.

Check Out UPSC CSE Books From PW Store

Challenges in Coal Gasification

- Environmental Factors: According to some studies, coal gasification actually generates more CO2 than a conventional coal power station.

- Quality of Coal: High ash content of Indian coal is a crucial barrier in the development of suitable technology.

- Induced Subsidence: The void created by deep mining during the coal gasification process may cause significant deformation both in the remaining coal and surrounding rocks.

- Heating, quenching, water flux and potential roof and wall collapse may seriously compromise the integrity of the cavity leading to a subsidence.

- Occupational hazard: Coal Gasification process cannot be controlled to the same extent as surface gasifiers which poses the risk on account of high temperature and pressure in the cavity which furthers the risk for the workers.

- Groundwater Contamination: While the nation already faces a water scarcity, coal gasification is one of the more water-intensive energy generation methods.

- Economy of Project: It is an inherently ‘unsteady’ state process and both the flow rate and the heating value of the product gas will vary over time.

- Changes in the quantity and quality of gas produced will have a significant impact on the economics of the project.

- Technological Concern: Lack of availability of proven gasification technology suitable for Indian poor-quality Coal

Read More About: Cabinet Approves Rs 8500 Cr for Coal Gasification Projects

![]() 28 Jun 2024

28 Jun 2024