Researchers have found an eco-friendly approach that can eliminate the use of toxic chemicals in silk processing.

About New Research: This new research, published in Chemistry Select by Wiley Publishers, has the potential to be used in sericin extraction from both mulberry (Bombyx mori) and non-mulberry silks, such as Muga (Antheraea assamensis) and Eri (Philosamia ricini), indigenous to Northeast India.

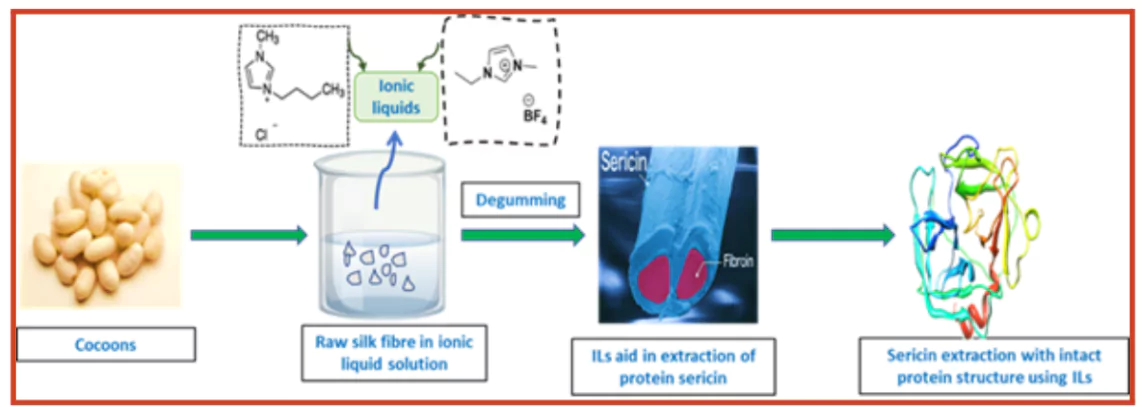

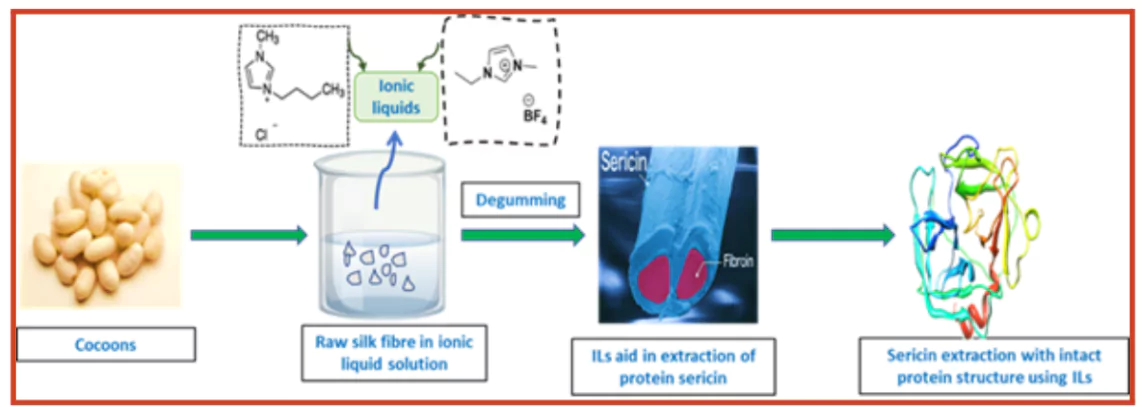

- Traditional Silk Protein Extraction: Traditionally, toxic chemicals like sodium carbonate, sodium hydroxide, sulfuric acid, and lithium bromide have been used to extract silk proteins, fibroin and sericin from various types of raw silk fibres, an important step in the process of making silk from cocoons.

- Sericin Removal from Silk: Researchers studied six different ILs and found that 1-Butyl-3-methylimidazolium chloride (BMIM.Cl), 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIM.BF4), and Tetraethylammonium bromide (TEAB) were particularly effective in removing sericin from silk fibres, with TEAB showing exceptional ability to destabilise sericin proteins.

- Significance: The research holds great significance for the silk industry.

- It offers a more environmentally friendly alternative to traditional chemical methods. It paves the way for efficient sericin extraction from non-mulberry silks, potentially leading to new applications for these unique fibres.

Enroll now for UPSC Online Course

Silk Production in India

- India is the second-largest producer of silk in the world. Its total silk production during 2021-2022 was 34,903 MT.

- Karnataka contributed around 32% of the total silk production in the country during 2021-22. This was followed by Andhra Pradesh which had a share of 25% in the overall silk production during 2021-22.

The country produces four types of natural silks:

- Mulberry: The purest form of silk extracted from Silkworms, usually produced in yellow, white, or greenish-yellow colour.

- Tasar: It is a type of wild silk made from silkworms that feed on plants like Asan and Arjun. People from different parts of India call it tusaar, tusser, tushar, tusa, tassore, and tasar etc.

- Eri: Also known as Errandi and Endi in most parts of India, Eri Silk is one of the purest forms of silk from the East, with a dull yellow, gold-like sheen.

- Muga: Produced only in Assam, Muga silk yarns are totally yellow in colour. They are considered India’s strongest natural fibre and prerogative.

Government Initiatives for the Promotion of Sericulture

For the development and growth of the silk industry in India, the government has implemented several research & development, training, transfer of technology and IT initiatives:

a) Silk Samagra:

- Silk Samagra is an Integrated Scheme for Development of Silk Industry (ISDSI) which the Government of India introduced through Central Silk Board (CSB).

Central Silk Board (CSB):

- It is a Statutory body established in 1948 by an Act of Parliament.

- It is working under the administrative control of the Ministry of Textiles, Government of India.

|

- It aimed at the complete development of the silk industry in India.

- This scheme will improve the quality and productivity of silk production and aid in scaling up production.

Check Out UPSC CSE Books From PW Store

b) Sericulture Development in the North-Eastern States (NERTPS)

- The Government of India has launched the sericulture development scheme within an umbrella scheme, namely the “North-East Region Textile Promotion Scheme”.

- This scheme’s objective is to revive, expand, and diversify sericulture in the state, with a special focus on Eri and Muga silks.

![]() 13 Jul 2024

13 Jul 2024