Answer:

| Approach:

Introduction

- Initiate with a brief explanation of what FRP composites are, including the components involved in their formation.

Body

- Describe the step-by-step manufacturing process of FRP composites.

- Discuss the applications of FRP composites in the aviation and automobile industry.

- Provide real-world examples that demonstrate the use of FRP composites within the Indian aviation and automobile sectors.

Conclusion

- Summarize by highlighting the increasing significance of FRP composites in industries where strength, durability, and lightweight characteristics are paramount.

|

Introduction:

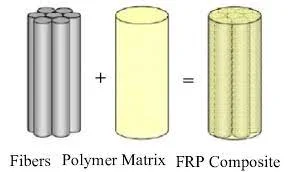

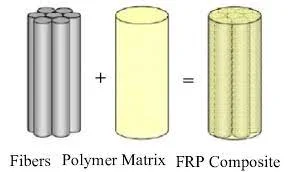

Fibre Reinforced Polymer (FRP) composites are materials made from two distinct components – a matrix (often a plastic like epoxy, polyester, or nylon) and a reinforcing fibrous material (like glass or carbon fibers). The result is a light, strong, and durable material with superior mechanical properties.

Body:

Manufacturing of FRP Composites:

- Moulding: A mould of the desired shape is prepared.

- Laying the Fibres: The fibres are laid in the mould. These can be unidirectional, bidirectional, or randomly oriented.

- Adding the Matrix: The matrix material is then added, which can be done via processes like hand lay-up, spray-up, pultrusion, filament winding, or injection moulding.

- Curing: The composite is then left to cure, hardening into its final form.

Applications in Aviation and Automobile Industry:

- Aviation: FRP composites are extensively used in the aviation industry due to their high strength-to-weight ratio. They are used in the manufacturing of aircraft bodies, interior components, and more.

- For example, the Boeing 787 Dreamliner is made up of 50% FRP composites by weight.

- Automobile Industry: In the automotive industry, FRP composites are used to make lightweight vehicle components. They are used in body panels, interior components, and structural parts.

- For instance, high-performance cars often feature carbon-fibre body parts.

A few examples:

- Aviation: In India, the National Aerospace Laboratories (NAL) has been using FRP composites for manufacturing aircraft components.

- Automobile Industry: Indian automobile companies, like Mahindra & Mahindra, have started to incorporate FRP components in their vehicles for weight reduction and fuel efficiency.

Conclusion:

FRP composites, with their unique characteristics, have found extensive applications in industries where strength, durability, and lightweight are crucial. As India advances in sectors like aviation and automobile manufacturing, the role of FRP composites is expected to grow, contributing to the production of efficient and high-performance products.