Researchers documented a new kind of sedimentary rock made from coastal slag deposits in the U.K. published in the journal Sedimentological.

Carbon Trapping and Lithification in Warton Slag

- Study Focus: Researchers studied slag samples from Warton, England, to analyse lithification processes and carbon-trapping potential Techniques Used: Analytical methods like X-ray diffraction, thermogravimetric analysis, isotope analysis, and electron microscopy were employed to understand slag composition and mineral content.

Enroll now for UPSC Online Course

Lithification

- Lithification: Lithification is the process by which sediments combine to form sedimentary rocks.

- Compaction is a consolidation of sediments due to the intense pressing weight of overlying deposits.

- With compaction, sediment grains get squished together, reducing the size of the original pore space that divided them.

- Slag hardens into sedimentary rock over time, contributing to artificial ground.

|

- Calcite Cement Precipitation: On the slag surface and sea-facing sides, calcium reacts with CO2 to form calcite, trapping carbon from the atmosphere.

- Calcium-Silicate-Hydrate (CSH) Precipitation: In the intertidal zone, slag forms CSH minerals, influenced by seawater, limiting harmful metal release.

The Anthropocene Era and Human Impact

Check Out UPSC NCERT Textbooks From PW Store

Slag

Slag is a byproduct formed during the smelting or other combustion and metallurgical processes.

It is essentially a molten material that forms when impurities and gangue (unwanted minerals) in ores are separated from the desired metal.

It primarily consists of oxides of elements like sulphur, phosphorus, silicon, and aluminium. It can also contain metal phosphates or silicates.

Uses of Slag

- Concrete: Slag can be reused to make concrete for road building.

- Fertiliser: Slag with a high phosphate content can be used as a plant fertiliser.

- Other Applications: Slag can also be used in various industrial applications, such as making bricks, insulation materials, and glass.

Examples of Slag

- Steelmaking: In steelmaking, CaO and MgCO3 are added to the ore to neutralise alumina and silica in the metal and remove phosphorus and sulphur impurities.

- The resulting slag is typically a mixture of calcium silicate and magnesium silicate.

- Copper and Lead Smelting: The smelting of copper and lead ores often produces a slag containing iron and silica.

- This slag can be further processed to recover valuable metals or used in construction materials.

|

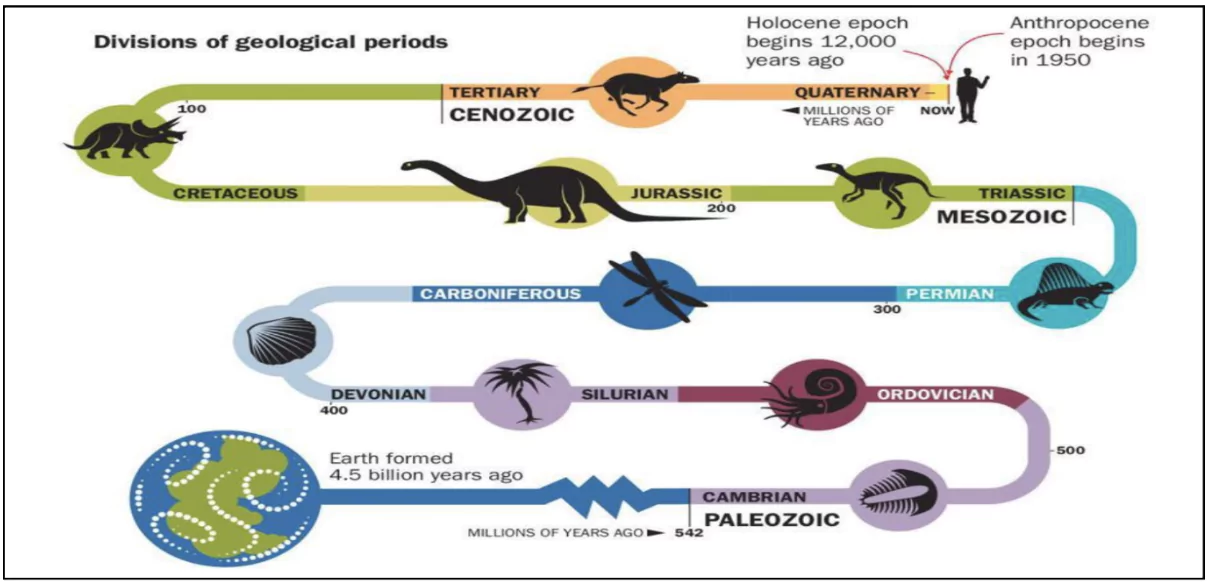

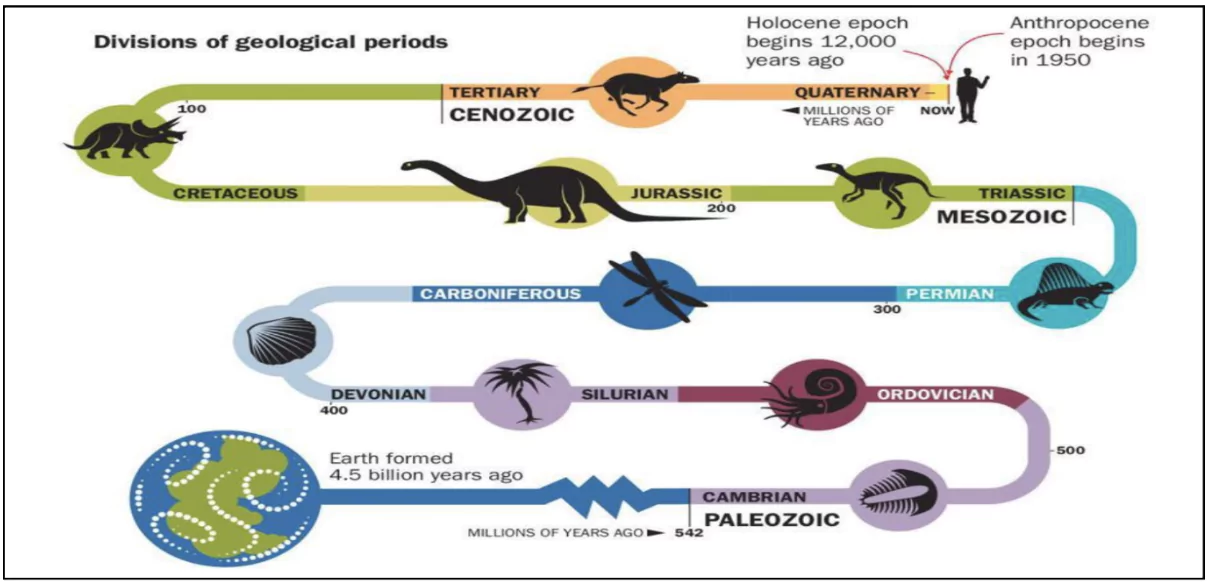

- Anthropocene Epoch: It is a proposed geological epoch beginning around the 1950s which marks a period where human activities have significantly impacted the Earth’s systems.

- Human Impact: Human activities, such as industrialization, agriculture, and urbanisation, have dramatically altered the planet’s landscapes, ecosystems, and climate.

- Industrial Waste: The rise of industries has led to the production of vast amounts of waste, including slag, which has been deposited on the Earth’s surface, contributing to the formation of new sedimentary materials.

- Artificial Deposits: Human-created deposits, like slag, now surpass natural sources of sedimentary materials, indicating the profound influence of human activities on the geological record.

- Global Changes: The Anthropocene is characterised by widespread environmental changes, including global warming, deforestation, pollution, and biodiversity loss.

- Geological Markers: Scientists are searching for distinct geological markers, such as elevated levels of radioactive isotopes, microplastics, or altered sediment layers, to define the start of the Anthropocene.

How does it capture Carbon?

- Carbon Sequestration: Slag can capture CO2 through mineral carbonation, helping reduce greenhouse gases.

- Toxic Metal Containment: Lithified slag can limit the release of harmful metals like vanadium and chromium.

Enroll now for UPSC Online Classes

Future Applications

- Coastal Protection: Slag deposits could be used to protect shorelines from erosion, combining environmental protection with waste management.

- Carbon Capture: Understanding lithification processes can help repurpose slag for CO2 sequestration without the need for additional facilities.

- Resource Recovery: Analyzing slag deposits may also help in recovering valuable resources for recycling in steelmaking.

![]() 11 Oct 2024

11 Oct 2024