The adoption of E20 (20% ethanol-blended petrol) in India has sparked concerns about vehicle compatibility and insurance claim denials for engine damage caused by using incompatible fuel blends.

What is Ethanol (C2H5OH)?

- Ethanol is a renewable, bio-based alcohol fuel produced through the fermentation of sugars found in crops like sugarcane, maize, and rice.

- It serves as an alternative to fossil fuels, aiming to reduce greenhouse gas emissions and dependence on imported oil.

Sources of Ethanol Production

- First-Generation (1G): Sugarcane, maize, and rice.

- Second-Generation (2G): Agricultural residues, such as rice straw and corn cobs.

- Third-Generation (3G): Algae and other advanced biofuels.

How is Ethanol Produced?

- Fermentation: Sugars from feedstocks are fermented by yeast to produce ethanol.

- Distillation: The fermented mixture is distilled to separate ethanol from other components.

- Dehydration: The distilled ethanol is dehydrated to remove water, producing anhydrous ethanol suitable for blending with petrol.

Current Status of Ethanol Production in India

- Production Capacity: Ethanol production capacity has more than doubled in four years, reaching 16,230 million litres.

- Blending Achievements: Ethanol blending in petrol increased from 1.53% in 2013–14 to 20% in 2025.

- Economic Impact: Savings of approximately ₹1.36 lakh crore in foreign exchange due to reduced oil imports.

- Rural Development: Disbursement of ₹1.18 lakh crore to farmers and ₹1.96 lakh crore to distilleries, boosting rural incomes.

History of Ethanol Blending in India

- 1970s–2000s: Ethanol blending in India began in response to the oil crises, aiming to reduce dependence on imported oil.

- In 2003, the government launched the Ethanol Blended Petrol (EBP) Programme with an initial target of 5% ethanol blending.

- 2010s: The target was raised to 10%, but slow progress was seen due to challenges like inconsistent ethanol production and distribution issues.

- 2020s: In 2018, India set a target of 20% blending by 2030, later advancing it to 2025–26.

- By 2025, India achieved 20% ethanol blending, five years ahead of schedule.

Progress and Achievements

- Blending Levels: In the month of July 2025, Ethanol blending of 19.93% has been achieved; on track to reach 20% by 2025.

- Production Capacity: Ethanol production capacity more than doubled in four years, reaching 16,230 million litres.

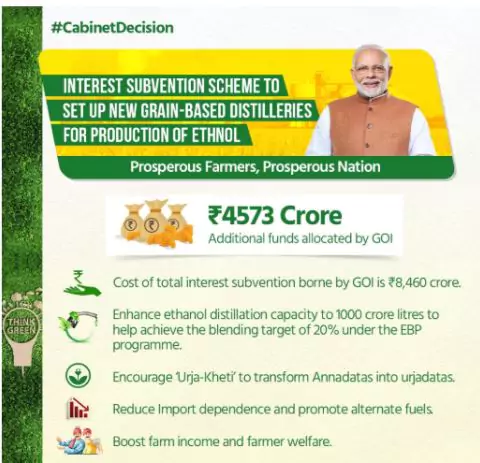

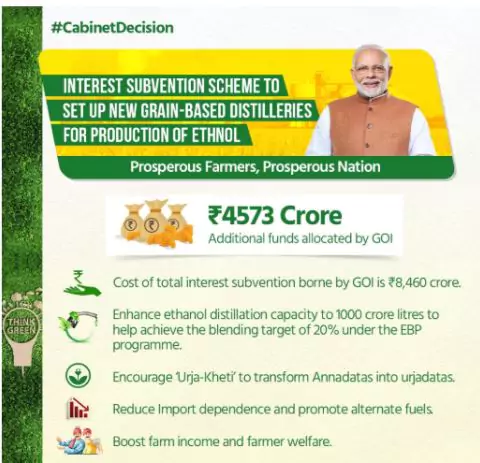

- Infrastructure Investment: ₹40,000 crore invested since 2014 to set up ethanol distilleries.

- Policy Support: Government notified a lower price for rice supplied to ethanol producers to boost production.

- Approval by Government for allocation of 52 Lakh Metric Tonne (LMT) of surplus Food Corporation of India (FCI) rice for ethanol production.

- Diversion of 40 LMT of sugar for ethanol production allowed for 2024-25.

- E27 Ethanol Blending: The government plans to introduce guidelines for 27% ethanol blending (E27) in petrol by August 2025

Benefits and Significance of Ethanol Blending

- Energy Security Enhancement: Ethanol blending reduces reliance on imported crude oil, enhancing national energy security.

- Achieving 20% ethanol blending is projected to save approximately $4 billion (₹30,000 crore) annually in foreign exchange.

- Reduction in Greenhouse Gas Emissions: Ethanol burns cleaner than gasoline, leading to lower emissions of carbon dioxide and other pollutants.

- The adoption of E20 fuel is expected to reduce CO₂ emissions by 69.8 million tonnes annually.

- Support for Rural Economy and Farmers: Increased demand for ethanol boosts income for farmers, especially those producing surplus crops.

- The government has disbursed over ₹1.18 lakh crore to farmers through the Ethanol Blended Petrol (EBP) Programme.

- Promotion of Sustainable Agriculture: Utilizing agricultural residues and surplus grains for ethanol production promotes sustainable farming practices.

- The National Policy on Biofuels encourages the use of feedstocks like maize, broken rice, and sugarcane juice for ethanol production.

- Technological Advancements in the Automotive Sector: The introduction of flex-fuel vehicles capable of running on high ethanol blends fosters innovation in the automotive industry.

- Automakers are developing vehicles compatible with ethanol blends up to E85, aligning with global standards.

- Alignment with Global Sustainability Goals: Ethanol blending aligns with India’s commitments to reduce carbon emissions and promote renewable energy.

- India’s participation in the Global Biofuels Alliance underscores its dedication to sustainable energy practices.

Vehicle Compatibility and Performance

- Material Durability Issues: Ethanol can corrode fuel systems and affect material durability, although engineering solutions exist to mitigate this.

- Compatibility with Older Vehicles: Studies show vehicles manufactured to Euro 2, U.S. Tier 1, and India’s BS 2 standards (since 2001) can handle ethanol up to E15.

- BS 2 and BS 6 Norms: Vehicles under BS 2 have fuel control systems that can handle ethanol more efficiently.

- Newer Standards (E20): Vehicles manufactured since 2023 are designed to handle E20. However, there is no clear policy regarding older vehicles (E5 models).

Issues and Concerns of Ethanol Blending

- Food Security Risks: Diversion of food grains like maize and rice for ethanol production may impact food availability.

- The shift towards maize cultivation has led to a 4% decrease in oilseed acreage, potentially affecting edible oil production.

- Water Resource Depletion: Ethanol production from water-intensive crops like sugarcane and rice strains water resources.

- Sugarcane cultivation requires approximately 2,500 liters of water per kilogram of sugar produced, leading to groundwater depletion.

- Impact on Edible Oil Self-Sufficiency: Increased maize cultivation for ethanol production may reduce the area under oilseeds.

- India’s goal of achieving 72% edible oil self-sufficiency by 2030–31 is at risk due to declining oilseed acreage.

- Consumer Concerns Over Vehicle Compatibility: Older vehicles may face performance issues when using higher ethanol blends.

- Studies indicate a 1–2% decrease in fuel efficiency for vehicles designed for E10 when using E20 fuel.

- Many vehicle owners are still unaware of the compatibility of their vehicles with ethanol blends, leading to skepticism and reluctance to use ethanol-blended fuel, despite the government’s efforts to promote it.

- Insurance Claim Denials: Some insurance companies deny claims for engine damage due to the use of incompatible ethanol-blended fuels.

- Instances have been reported where insurers cited “incorrect fuel usage” as grounds for claim rejection.

- Lack of Consumer Awareness: Insufficient information on ethanol-blended fuels may lead to misuse and vehicle damage.

- There is a need for widespread consumer education on the benefits and compatibility of ethanol-blended fuels.

- Infrastructure Challenges: Limited infrastructure for ethanol production and distribution may hinder the blending process.

- Investment in infrastructure is crucial to support the scaling up of ethanol blending initiatives.

Comparison with Other Alternative Fuels

| Fuel Type |

Ethanol |

Electric Vehicles (EVs) |

Compressed Natural Gas (CNG) |

| Production Source |

Renewable biofuel, primarily from sugarcane, maize, and agricultural residues. |

Electricity (use fossil fuels). |

Derived from fossil fuel (natural gas). |

| Emissions |

Reduces CO₂ emissions compared to fossil fuels. |

Zero tailpipe emissions. |

Burns cleaner than petrol, but still fossil-based. |

| Infrastructure |

Compatible with existing fuel infrastructure. |

Requires extensive charging infrastructure. |

Requires CNG infrastructure. |

| Technology Fit |

Compatible with existing petrol vehicles, including flex-fuel vehicles. |

Requires new technology and vehicle designs. |

Compatible with existing vehicles. |

| Sustainability |

Renewable, helps support rural economies and agriculture. |

Dependent on the electricity grid and resource-intensive batteries. |

Non-renewable, reliant on natural gas reserves. |

| Cost |

Generally lower than electric vehicles or hydrogen. |

High upfront cost, dependent on battery technology. |

Generally cheaper than petrol or diesel. |

Key Government Initiatives on Ethanol Production and Blending

- National Policy on Biofuels – 2018 (Amended 2022)

- Objective: To promote the use of biofuels, including ethanol, in India.

- Targets: Set a target of 20% ethanol blending in petrol by 2025 and 5% biodiesel blending by 2030.

- Sustainability Focus: Encourages the use of non-food feedstocks for ethanol to address food security concerns.

- Ethanol Blended Petrol (EBP) Programme – 2003

- Objective: To reduce dependence on imported crude oil and promote sustainable agriculture.

- Target: Achieved 14.6% ethanol blending in petrol 2023-24, with the target of 20% by 2025.

- Amendment in Pradhan Mantri JI-VAN Yojana

- Modified scheme extends timeline for implementation of scheme by 5 year i.e. till 2028-29

- Financial support to Advanced Biofuel Projects using lignocellulosic biomass and other renewable feedstock.

Global Success in Ethanol Blending

Brazil: A Pioneer in Ethanol Blending

- Proálcool Program (1975): Brazil initiated the Proálcool Program in the 1970s to reduce oil imports by promoting ethanol production from sugarcane.

- According to Bloomberg reports from 2023 and 2025, flex-fuel vehicles dominate the Brazilian market, constituting approximately 84.5 per cent of all vehicle sales as of 2025.

United States: Scaling Up Ethanol Production

- The US mainstreamed E10 (10 per cent ethanol) under its Renewable Fuel Standard from 2005, with corn as the primary ethanol source.

- E10, a blend of 10 per cent ethanol and 90 per cent gasoline, is widely available at most fuel stations across the country.

- Offer E85 or flex fuel, which contains between 51 per cent and 83 per cent ethanol, varying by region and season.

European Union: Diverse Approaches to Ethanol Blending

- Blending Mandates: Countries like the Netherlands, Norway, Poland, Romania, and Slovakia have implemented ethanol blending mandates ranging from 18% to 27.5%, depending on market conditions.

|

Way Forward

- Diversification of Feedstocks: Encourage the use of non-food feedstocks to mitigate food security concerns.

- The National Policy on Biofuels promotes the use of agricultural residues and non-food crops for ethanol production.

- Technological Innovation: Invest in research and development to improve ethanol production efficiency and vehicle compatibility.

- The government is supporting innovation in biofuel technologies through various schemes.

- Infrastructure Enhancement: Develop robust infrastructure for the production, storage, and distribution of ethanol-blended fuels.

- Public Sector Oil Marketing Companies (OMCs) are expanding infrastructure to support ethanol blending.

- Policy Harmonization: Align policies and regulations to create a conducive environment for ethanol blending.

- The National Policy on Biofuels has been amended to provide a clear framework for ethanol blending.

- Public Engagement: Conduct awareness campaigns to educate consumers about the benefits and safety of ethanol-blended fuels.

- The government is promoting the use of ethanol-blended fuels through various initiatives.

- Insurance Reforms: Collaborate with insurance companies to address concerns related to ethanol-blended fuels.

- Discussions are ongoing to ensure that insurance policies cover damages related to ethanol-blended fuels.

- Monitoring and Evaluation: Establish mechanisms to monitor the impact of ethanol blending on various sectors and make necessary adjustments.

- The government is conducting studies to assess the impact of ethanol blending and make informed decisions.

Conclusion

India’s ethanol blending initiative presents an opportunity to enhance energy security, reduce emissions, and promote rural development. However, addressing challenges related to feedstock availability, infrastructure, and public perception is crucial for the sustainable success of the program.

![]() 12 Aug 2025

12 Aug 2025