The ongoing “fifth industrial revolution” is going to augur well for the Indian manufacturing sector, helping increase the revenues of Indian manufacturers by 6.42% over the next two years, according to the PwC report.

Key Findings of the report

- Industry-Wide Sustainability Drive: 93% of manufacturers are adopting Industry 5.0 to integrate sustainability, using digital technology to incorporate renewable energy sources and enhance energy efficiency.

- Over half of the manufacturers are prioritizing sustainability investments in 2024, reflecting an industry-wide shift toward sustainable growth.

- Financial and Operational Impact: Industry 5.0 adoption could lead to a projected 6.42% revenue increase over the next two years.

- Without such capabilities, manufacturers missed an estimated 4.37% of FY24 revenues.

- Focus on Workforce Development: 52% of senior executives prioritize fostering a culture of lifelong learning to build a resilient workforce skilled in advanced technologies, supporting long-term sustainability goals.

- Sector-Specific Insights: The cement and industrial goods industries lead in adopting real-time tracking systems, with 95% of manufacturers implementing tech-driven inventory management to boost responsive supply chains and sustainable operations.

- Implications for the Manufacturing Sector: Industry 5.0 is positioned as a transformative approach, aligning sustainability with profit growth, responsive supply chains, and a resilient, tech-savvy workforce.

- These features are crucial for maintaining competitiveness and operational sustainability in a rapidly evolving market.

Enroll now for UPSC Online Classes

Challenges and Barriers in implementation of Fifth Industrial Revolution (IR 5.0)

- Technology Access and Cybersecurity: Adoption of Generative AI remains challenging, with secure access posing a barrier across various sectors, including chemicals, textiles, cement, and automotive.

- Cybersecurity is a significant concern, with 46% of executives focusing on data protection and operational integrity to mitigate risks.

- Resilience through Human-Machine Synergy:Executives view Industry 5.0 as offering a competitive advantage by enhancing productivity and enabling human-machine collaboration, which is key to resilience and long-term sustainability.

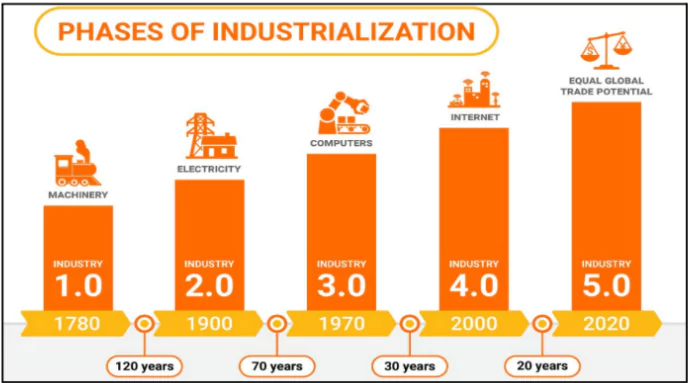

About Fifth Industrial Revolution (IR 5.0)

- Industry 5.0: A phase of industrialization focused on human and machine collaboration to improve efficiency, sustainability, and personalization

- Builds on Industry 4.0, emphasizing human-centeredness, sustainability, and ethical progress

Key Technological Shifts enabling Fifth Industrial Revolution (IR 5.0)

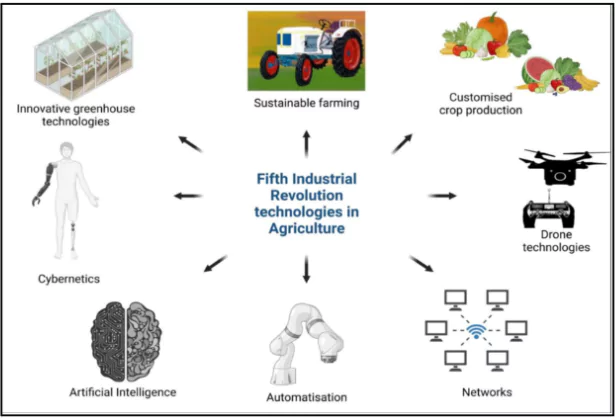

- AI and Robotics: Automation gives humans more leisure and creative roles.

Edge Computing: Processes data near its source, reducing latency and meeting privacy needs.

Edge Computing: Processes data near its source, reducing latency and meeting privacy needs.- 5G/6G and Brain-Computer Interfaces: Enhance connectivity and open new communication channels.

- Remote Work (“Cloud People”): Remote work will be commonplace, with virtual and cloud-based roles.

- Lean Management by Machines: Efficiency-driven AI enables lean, waste-reducing processes.

- Sustainable, Connected Systems

- IoT and Big Data: Enable real-time tracking, asset management, and reduced waste.

- 3D Printing and Blockchain: Improve production customization, transparency, and resource optimization.

Check Out UPSC NCERT Textbooks From PW Store

Government Initiatives in India

- Skill India and National Apprenticeship Promotion Scheme

- Policies to attract foreign investments, streamline regulations, and foster innovation

![]() 26 Oct 2024

26 Oct 2024

Edge Computing: Processes data near its source, reducing latency and meeting privacy needs.

Edge Computing: Processes data near its source, reducing latency and meeting privacy needs.