Context:

- The evaluation studies carried out for relevant component schemes of Pradhan Mantri Kisan SAMPADA Yojana (PMKSY) has revealed that substantial direct/indirect employment opportunities have been created in projects supported through its relevant component schemes.

| Probable Question:

Q. Although the food processing industry in India has experienced steady growth, there is still significant untapped potential to be realised. Examine. (250 words) |

Food Processing Industry:

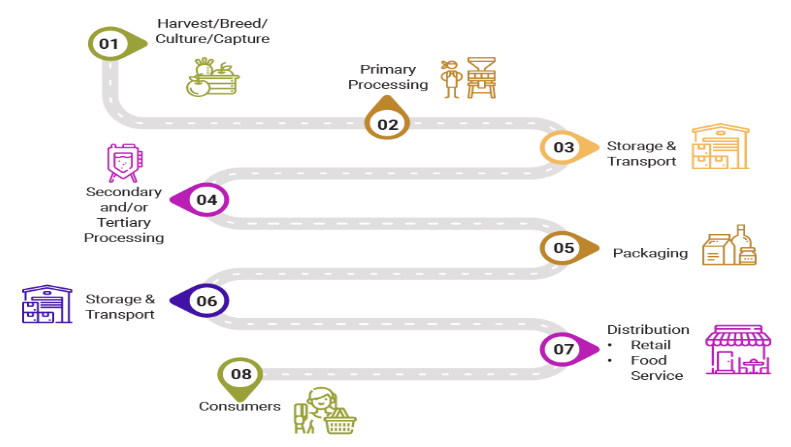

- It is responsible for converting raw ingredients or agricultural products into edible food items suitable for human consumption. It plays a vital role in processing and preserving perishable materials, resulting in packaged food products with an extended shelf life, making them convenient for distribution and consumption.

Enroll now for UPSC Online Course

About food processing industry:

- Sunrise Industry: The Food Processing Industry is a sunrise industry (burgeoning in its infancy stage that shows promise of a rapid boom) providing vital linkages between the two pillars of our economy – manufacturing and agriculture.

- High Growth: The Food Processing industry in India is undergoing a significant transformation. With a turnover of $110 billion, it accounts for 35 per cent of the Indian food market, and has been growing at a better rate of 14 per cent in the last few years.

Key Facts:

- Sector Growth: Its output is expected to reach US$ 535 billion by 2025-26.The Indian food industry is expanding at a CAGR of 11% and the food processing sector accounts for 32% of the total food industry.

Job creation: This sector is expected to generate 9 million jobs by 2024.

Job creation: This sector is expected to generate 9 million jobs by 2024.- FDI: India’s food sector attracted US$ 4.18 billion in foreign direct investments between April 2014 and March 2020.

- Consumer Base: By 2030, Indian annual household consumption is expected to triple, making India the fifth-largest consumer in the world.

Key Drivers:

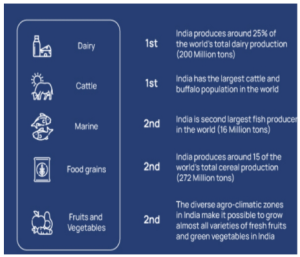

- Surplus raw material: High level of agricultural production – large livestock base, wide variety of crops, inland water bodies and a long coastline, that help increase marine production

- Strong domestic demand: Changing lifestyle and food habits due to increased disposable income.

- Export opportunities: There is a rise in the demand for Indian processed food in the international market. In addition to changing consumer tastes in foreign markets, huge demand from people of Indian origin live abroad. According to government’s estimates, Indian exports of processed food and related items rose at a compound annual growth rate (CAGR) of 11.74 percent during 2011-16, reaching US$16.2 billion.

- Availability of cheap workforce: India has a relatively cheaper workforce that can be effectively utilized to set-up a low production base for the domestic and export market. Production costs in India are lower by about 40 percent in comparison to most developed and developing countries

Opportunities:

- Reducing food wastage: The food processing industry can play a vital role in reducing food wastage and improving food security.

- Feeding the population: India faces the challenge of feeding a growing population, and a significant amount of agricultural produce is lost due to spoilage and inadequate storage facilities. By investing in advanced processing and preservation techniques, the industry can help minimize post-harvest losses and ensure a steady supply of food throughout the year.

- Employment Opportunities: Food processing industry also holds a great potential to generate employment opportunities, particularly in rural areas. A parliamentary report from 2022 highlighted that the food processing industry is a major segment in terms of employment, accounting for 12.38% of the jobs generated in the Registered Factory sector in 2017-18.

- Entrepreneurship: With proper training and skill development programs, individuals can be empowered to become entrepreneurs, contributing to local economic development. This not only creates jobs but also addresses the issue of rural-urban migration.

- Growth Acceleration: The food processing industry can provide an immense acceleration to India’s economy. Although the industry has experienced steady growth, there is still significant untapped potential to be realized.

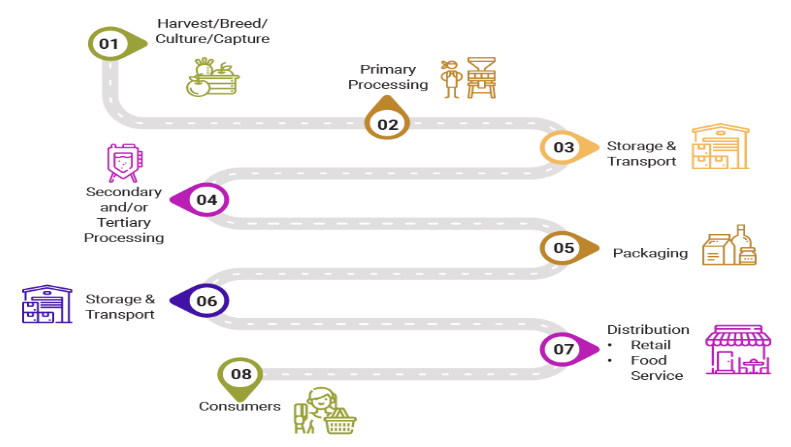

Upstream requirements of Food processing industry:

- Accessibility to raw materials

- Modern extraction techniques.

- Good linkages with farmers.

- Raw materials

- Good quality testing facilities.

- Transport facilities

- Work force.

Enroll now for UPSC Online Classes

Downstream Requirements in Food processing industry:

- Processing of the materials collected during the upstream stage into a finished product.

- Actual sale of product to customers like businesses, governments or individuals.

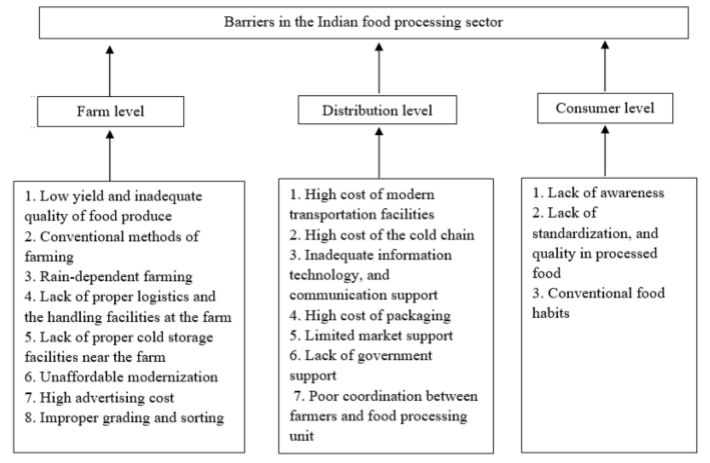

Challenges of food processing industry in India:

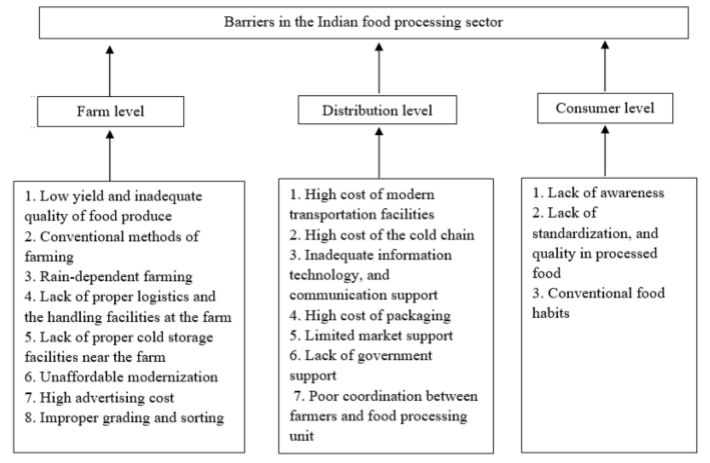

- Supply Side Issues: Small and dispersed marketable surplus due to fragmented holdings, low farm productivity, high seasonality, perishability and intermediation result in lack of distribution on supply and quality, and in turn, impede processing and exports

- Infrastructure bottlenecks: Inadequate logistics and cold chain infrastructure, which results in the loss of more than 30 percent of the produce from the farm, inadequate primary processing, storage and distribution facilities, transportation of perishable products due to reliance on traditional modes of transport instead of specialized vehicles such as reefer vans.

- Poor supply chain linkages: India’s agriculture market has a long and fragmented supply chain that results in high wastage and high costs, especially due to seasonality, perishability, and variability of produce.

- Supply side advantages: High level of agricultural production – large livestock base, wide variety of crops, inland water bodies and a long coastline, that help increase marine production.

- Lack of skilled manpower: The food processing industry (FPI) has a large unorganized segment, and to explain to them the inefficiencies in the existing production system and invest in technology upgrades becomes a challenge. Many food processing businesses operate in the small and medium enterprises (SMEs) sector, which often lacks the resources needed to upgrade their facilities and machinery to the latest technology.

- Deficiencies in the regulatory environment: Numerous laws, under the jurisdiction of different ministries and departments, govern food safety and packaging. The multiplicity of legislation leads to contradictions in specifications, conflicting approach, lack of co-ordination and administrative delays. Limited knowledge about the quality certifications required for the export markets.

- Demand Side Issues: There is negative perception on consumers regarding the nutritional value of the ready to eat food. The younger generation has often been prohibited from consuming packaged ready-to-eat products, affecting overall demand and sales in India.

- Low brand value and strength: Indian brands have little to no strength in the foreign markets with only Indian-origin people being able to recognise the Indian food brands and products.

GOVERNMENT INITIATIVES:

- FDI POLICY:

- 100 % FDI permitted for food processing

- 100 % FDI under government approval route for trading, including the same through e-commerce, with respect to food products manufactured and/or produced in India

- PRADHAN MANTRI KISAN SAMPADA YOJNA (PMKSY):

- The initiative aims to create modern infrastructure for food processing and preservation, improve access to finance for food processing SMEs, and provide training and technical assistance to these enterprises. The government has also set up a number of food parks and clusters, which provide a range of facilities and support services to food processing companies.

- Scheme for Mega Food Parks:

The Mega Food Parks Scheme covering a minimum area of 50 acres, operates using a cluster-based approach, following a hub and spokes model that aims to establish a vital link between agricultural production and the market. By bringing together farmers, processors, and retailers, the scheme seeks to maximize the value addition of agricultural products, minimize wastage, boost farmers’ income, and create employment opportunities, especially in rural areas.

The Mega Food Parks Scheme covering a minimum area of 50 acres, operates using a cluster-based approach, following a hub and spokes model that aims to establish a vital link between agricultural production and the market. By bringing together farmers, processors, and retailers, the scheme seeks to maximize the value addition of agricultural products, minimize wastage, boost farmers’ income, and create employment opportunities, especially in rural areas.

- Scheme for creation/ expansion of Food Processing and Preservation Capacities:

- Creation of processing and preservation capacities and modernization/ expansion of existing food processing units with a view to increasing the level of processing, value addition leading to reduction of wastage.

- Scheme for creation of backward and forward linkages:

- Provide effective and seamless backward and forward integration for processed food industry by plugging the gaps in supply chain in terms of availability of raw material and linkages with the market, financial assistance provided for setting up of primary processing centers/ collection centers at farm gate and modern retail outlets at the front end along with connectivity through insulated/ refrigerated transport.

- PM Formalisation of Micro food processing Enterprises (PMFME) Scheme:

- The scheme provides financial, technical and business support for setting up / upgradation of 2 lakh micro food processing enterprises in the country through credit linked subsidy during five years from 2020-21 to 2024-25 with an outlay of Rs. 10,000 cr.

- The Scheme of Cold Chain, Value Addition, and Preservation Infrastructure:

- It aims to establish a seamless and integrated cold chain system from the farm gate to the end consumer. This comprehensive infrastructure includes pre-cooling facilities at production sites, reefer vans, mobile cooling units, and value addition centers, ensuring the preservation and enhancement of agricultural products throughout the supply chain.

Enroll now for UPSC Online Course

Way Forward:

- Policy initiatives to plug supply side and infrastructure bottlenecks:

- Backward linkages: Fixing the broken supply chain by directly linking the farmers with food processing companies – by connecting demand with supply. Fostering development of backward linkages is crucial for securing scale and economic.

- Private sector participation: Private players should be involved, and they should work with the SHFs to perfectly assess the situation. Private players can help by investing in logistics and storage facilities, financing the activities needed to create and boost the brand value and strength of Indian food products in the export markets.

- Technology upgradation: Encourage technology up gradation of existing facilities and investment in development of ancillary industries like research and development, packaging, food processing equipment manufacturing, food safety certifying agencies by extending fiscal incentives to investors.

- Institutional credit: Enable better access to credit to facilitate the high cost technology adoption and scale enhancement.

- Awareness and capacity building: Raising awareness about new techniques and spreading efficient farming knowledge amongst the smallholder farmers (SHFs) is essential for limiting crop damage and for stopping the overuse of chemicals in the fields.

- Streamlining the regulatory structure:

- Single window clearance: Remove impediments of multiple departments and laws in seeking approvals by bringing them under a single window thereby providing clarity in roles and channels of operational and service delivery.

- Ensure uniform implementation of the APMC act to encourage private sector investment in infrastructure development.

- Human resource development-to meet increasing demand for skilled manpower:

- Professional courses: Encourage State Agricultural Universities to commence courses in food packaging, processing, bio-technology, information technology in agriculture and such allied fields.

- Joint Collaboration: Effective collaboration between the government and the industry is necessary to support the industry’s growth, benefiting not only the sector itself but also the agriculture industry and the overall economy.

News Source: pib

![]() 22 Jul 2023

22 Jul 2023

Job creation: This sector is expected to generate 9 million jobs by 2024.

Job creation: This sector is expected to generate 9 million jobs by 2024.

The Mega Food Parks Scheme covering a minimum area of 50 acres, operates using a cluster-based approach, following a hub and spokes model that aims to establish a vital link between agricultural production and the market. By bringing together farmers, processors, and retailers, the scheme seeks to maximize the value addition of agricultural products, minimize wastage, boost farmers’ income, and create employment opportunities, especially in rural areas.

The Mega Food Parks Scheme covering a minimum area of 50 acres, operates using a cluster-based approach, following a hub and spokes model that aims to establish a vital link between agricultural production and the market. By bringing together farmers, processors, and retailers, the scheme seeks to maximize the value addition of agricultural products, minimize wastage, boost farmers’ income, and create employment opportunities, especially in rural areas.