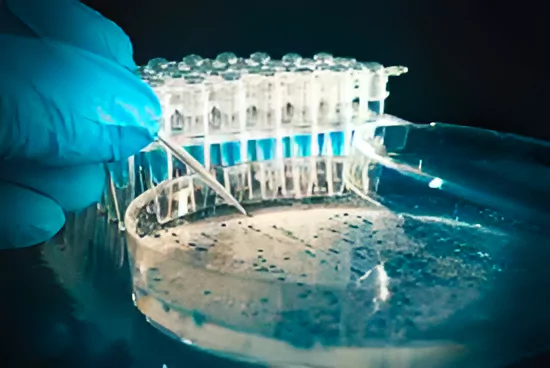

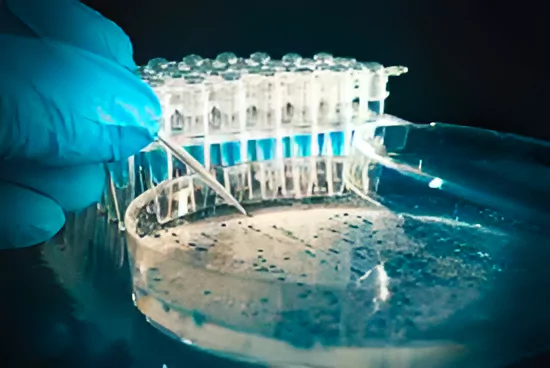

Researchers at the Department of Biochemistry, Indian Institute of Science (IISc) have developed a new method for producing recombinant proteins.

IISc finds safer way to mass produce recombinant proteins like insulin

- The new method utilizes monosodium glutamate (MSG), a common food additive, as a safer alternative to methanol in the production process.

- FDA Approval: Monosodium glutamate (MSG) is an FDA-approved food additive.

- Alternative Activation:

- Promoter Activation: MSG can activate a different promoter in the yeast genome.

- Target Enzyme: This promoter is responsible for coding the enzyme phosphoenolpyruvate carboxykinase (PEPCK).

- Comparison to Traditional Methods

- Protein Production: Activating the PEPCK promoter with MSG results in protein production comparable to the traditional methanol activation of the AOX promoter.

About Recombinant Proteins

- Recombinant proteins are artificially produced proteins.

- It is generated using cells engineered to contain a specific gene of interest.

- Gene Engineering: These cells are modified to carry and express the gene responsible for the desired protein.

- Examples include vaccine antigens, insulin, and monoclonal antibodies.

Enroll now for UPSC Online Course

Applications of Recombinant Proteins

- Therapeutic Applications

- Medicine: Recombinant proteins are essential for producing therapeutic proteins used in various medical treatments.

- Examples: These include insulin, hormones, antibodies, and clotting factors.

- Impact: They have revolutionized disease treatment, enabling synthetic insulin production for diabetes control and targeted therapies like monoclonal antibodies for precise cancer treatment.

- Biopharma Industry

- Biologic Drugs: Recombinant proteins are crucial for developing advanced biologic drugs, including monoclonal antibodies and recombinant vaccines.

- Diverse Treatments: These drugs provide precise and effective treatments for a wide range of diseases.

- Customization and Engineering

- Enhanced Properties: Recombinant proteins can be customized by modifying their sequences to improve properties such as solubility and production yield.

- Research and Drug Discovery

- Scientific Research: They are invaluable tools for studying protein function, interactions, and pathways, driving research and drug discovery.

- Industrial Applications

- Enzyme Production: Recombinant proteins are used in various industrial sectors, including enzyme production for industrial processes.

- Agriculture: They play a role in creating genetically modified organisms for agricultural applications.

Methanol-Induced Production of Recombinant Proteins (Old Method)

- Unique Promoter Mechanism:

- AOX Promoter: The yeast genome contains a specific gene region called the AOX promoter, which can be activated by methanol.

- Enzyme Coded: This promoter codes for the enzyme alcohol oxidase (AOX).

- Yeast: The yeast species Pichia pastoris is the most widely used organism for recombinant protein production.

- It is now known as Komagataella phaffii.

|

- Production Process:

- Production Method: These proteins are produced in large quantities by cultivating genetically modified bacterial, viral, or mammalian cells in large bioreactors.

- Gene Integration: For production, The gene coding for the desired protein is inserted into the yeast genome adjacent to the AOX promoter.

- Cell Growth: Carbon Source: Yeast cells are initially grown using glycerol or glucose as the carbon source.

- Activation: Once sufficient cell growth is achieved, methanol is added to activate the AOX promoter, leading to substantial production of the recombinant protein.

Challenges of Old Method for Producing Recombinant Proteins (Yeast Cell Factories)

- Methanol Dependence: The process relies on methanol, a flammable and toxic substance that requires careful handling and storage.

- Fire Risk: Methanol’s flammability increases the danger of accidents and fires during production.

- Harmful Byproducts: The process can sometimes generate hazardous byproducts that need additional treatment or disposal.

- Oxidative Stress: Methanol metabolism produces hydrogen peroxide, which can cause oxidative stress in yeast cells and potentially damage the recombinant proteins.

Enroll now for UPSC Online Classes

Benefits of the New Method for Producing Recombinant Proteins (Using MSG)

- Safer Alternative: It eliminates the need for methanol, a flammable and hazardous substance, reducing fire risk and safety concerns.

- Reduced Byproducts: Avoids the production of harmful byproducts and simplifies waste management.

- Potentially Milder on Cells: By using MSG instead of methanol, the process may be less stressful for the yeast cells, potentially leading to higher protein yields or improved protein quality.

- Familiar and Approved Substance: MSG is a common food additive already approved by the USFDA, potentially streamlining regulatory hurdles for large-scale production.

![]() 1 Jun 2024

1 Jun 2024