![]() 29 Dec 2025

29 Dec 2025

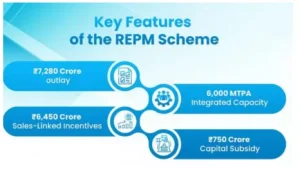

The Government of India has approved the ‘Scheme to Promote Manufacturing of Sintered Rare Earth Permanent Magnets’ (REPM).

Check Out UPSC CSE Books

Visit PW Store

Rare Earth Minerals

Why Are They “Rare Earth”?

|

<div class="new-fform">

</div>