With India’s carbon market set to launch in 2026, technologies for CO₂ removal are gaining attention. Biochar—a carbon-rich byproduct of pyrolyzing agricultural and municipal waste—is emerging as a scalable, sustainable solution for negative emissions.

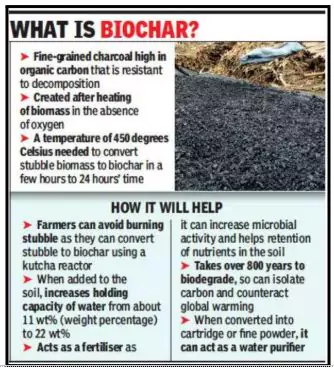

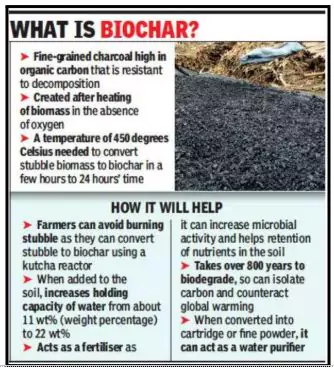

What is Biochar

- Biochar is a charcoal-like substance that’s made by burning organic material from agricultural and forestry wastes (also called biomass) in a controlled process.

- Biochar converts carbon into a stable form and is cleaner than other forms of charcoal.

- Raw Material: It is made from biomass sources like, wood chips, plant residues, manure or other agricultural waste products

- Byproducts: Syngas and bio-oil, usable for energy and fuel.

- Process: Biochar is produced during pyrolysis, a thermal decomposition of biomass in an oxygen-limited environment called pyrolysis.

- Physical Attributes: Biochar is black, highly porous, lightweight, fine-grained and 70 percent composed of carbon

- Properties: Rich in stable carbon, can persist in soil for 100–1,000 years.

Production Potential in India:

Production Potential in India:-

- India produces over 600 million metric tonnes of agricultural residue and 60 million metric tonnes of municipal solid waste annually.

- A large part of this is openly burned or dumped, leading to pollution and greenhouse gas emissions.

- Utilising 30–50% of this waste could yield 15–26 million tonnes of biochar each year and remove 0.1 gigatonnes of carbon dioxide-equivalent (GtCO₂e) annually.

- Byproducts and Energy Potential:

- Syngas: Generated during pyrolysis (20–30 million tonnes annually), syngas can produce 8–13 terawatt-hours (TWh) of electricity—0.5–0.7% of India’s annual electricity—replacing 0.4–0.7 million tonnes of coal.

- Bio-oil: Production of 24–40 million tonnes per year could offset 12–19 million tonnes of diesel or kerosene (about 8% of demand), reducing crude oil imports and over 2% of fossil-fuel emissions.

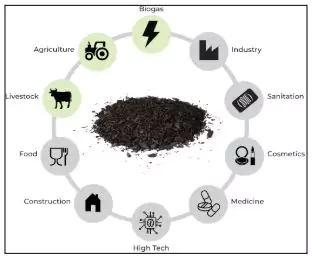

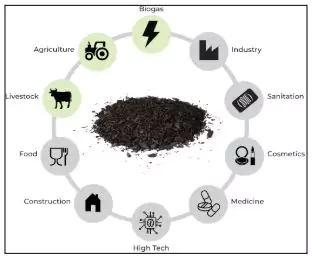

- Applications Across Various Sectors:

- Agriculture: Enhances soil moisture and fertility, especially in dry and degraded soils.

- Cuts nitrous oxide emissions by 30–50% (273× more potent than carbon dioxide)

- Reduces fertilizer need by 10–20% and increases crop yield by 10–25%

- Carbon Capture: Modified biochar can absorb carbon dioxide from industrial gases, though current efficiency is lower than conventional methods.

- Construction: Adding 2–5% biochar to concrete improves strength and heat resistance (increase by 20%) and captures ~115 kg CO₂ per cubic metre of concrete.

- Wastewater Treatment: One kilogram of biochar can treat 200–500 litres of water.

- With 70 billion litres of wastewater generated daily in India, this implies a demand of 2.5–6.3 million tonnes of biochar annually.

- Other Key Benefits:

- Long-term carbon sink (100–1,000 years).

- Reduces open burning, landfill emissions, and urban pollution.

- Byproducts contribute to energy security.

- Generates rural employment (potential: 5.2 lakh jobs through decentralised production units).

- Supports soil regeneration, water retention, and climate resilience.

- Challenges:

- No standardised feedstock or carbon accounting frameworks.

- Limited investor confidence in carbon credit eligibility.

- Weak monitoring and verification systems.

- Low awareness among stakeholders.

- Policy fragmentation across agriculture, energy, and climate sectors.

- Insufficient research and development for regional adaptation.

Way Forward

- Recognise biochar as a verifiable carbon removal method in India’s carbon market.

- Integrate into existing programmes: crop residue management, bioenergy schemes, and State Action Plans on Climate Change.

- Promote region-specific R&D on biomass and pyrolysis efficiency.

- Develop decentralised village-level units to boost rural livelihoods.

- Create co-benefit frameworks for soil, water, and emission improvements.

![]() 7 Aug 2025

7 Aug 2025

Production Potential in India:

Production Potential in India: