Core Demand of the Question

- Challenges that limit its effectiveness.

- Measures needed.

|

Answer

Introduction

As India targets 500 GW of non-fossil fuel capacity by 2030, the Production Linked Incentive (PLI) scheme has emerged as a key policy instrument to drive energy transition and manufacturing self-reliance. However, its performance in solar photovoltaic and battery manufacturing highlights structural and technological constraints that limit outcomes.

Body

Key challenges limiting PLI effectiveness in solar PV and battery sectors

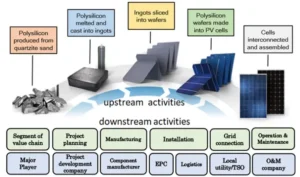

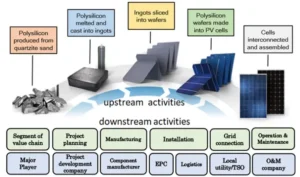

- Weak upstream manufacturing base: PLI gains are concentrated in module assembly, while critical upstream segments remain underdeveloped, sustaining import dependence.

Eg: By mid-2025, module assembly achieved 56% of targets, but polysilicon and wafer manufacturing reached only 14% and 10%.

- High technology and capital intensity: Upstream solar and battery manufacturing demands advanced processes, long gestation periods and high-risk capital investment beyond PLI timelines.

- Slow progress in battery cell manufacturing: Technical complexity and scale barriers have sharply delayed domestic battery production.

Eg: Only 1.4 GWh (about 2.8%) of the targeted 50 GWh battery capacity was commissioned by late 2025.

- Rigid domestic value addition norms: Aggressive localisation mandates increase compliance pressure without a ready supplier ecosystem.

Eg: Battery PLI requires 25% value addition in two years and 60% in five years.

- Shortage of specialised technical expertise: Limited domestic skill depth and constraints on foreign experts hinder timely execution.

Eg: Gigafactory projects faced delays due to non-availability of experienced Chinese technical experts.

Measures needed to strengthen high-technology green manufacturing

- Targeted support for upstream segments: High-risk upstream activities need capital subsidies and risk-sharing beyond output-linked incentives.

Eg: Government plans to de-risk polysilicon and wafer manufacturing through additional capital support.

- Shift focus from net worth to technical capability: PLI selection must prioritise technological competence, R&D depth and execution capacity.

- Long-term investment in R&D and skills: Sustainable manufacturing leadership requires continuous research funding and skilled workforce development.

Eg: Battery chemistry and gigafactory operations need years of cumulative technical learning.

- Facilitate strategic technology collaboration: Calibrated technology transfers and expert mobility can accelerate capability building.

- Align PLI timelines with industrial realities: Incentive frameworks must reflect long gestation periods of complex technologies.

Conclusion

To make the PLI scheme a true catalyst for green industrial transformation, India must move beyond short-term output incentives towards ecosystem creation. Strengthening upstream capabilities, embedding technical expertise, enabling selective collaboration, and aligning policy design with technological realities will allow India to evolve from an assembler to a globally competitive manufacturer of clean energy technologies.

To get PDF version, Please click on "Print PDF" button.

Latest Comments