![]() 16 Dec 2023

16 Dec 2023

Extraction of metals is a fundamental process that unveils the treasures hidden within the Earth’s crust.

Corrosion:

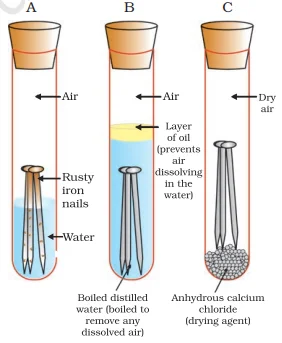

Rusting:

4Fe(s)+3O2 (from air)+xH2O(moisture)→2Fe2O3. xH2O(rust)

4Fe(s)+3O2 (from air)+xH2O(moisture)→2Fe2O3. xH2O(rust)

Oxidative Interactions of Copper with Atmospheric Gases: Formation of Green Copper Carbonate and Hydroxide

Cu(s)+H2O(moisture)+CO2(from air)→CuCO3.Cu(OH)2(green)

The Mechanism Behind Silver Corrosion in the Presence of Hydrogen Sulphide

Ag(s) + H2S(from air) →Ag2S(black) + H2(g)

Exploring the Unique Physical Properties of Nonmetals: An In-Depth Analysis

| Physical Properties of Nonmetals | Exceptions in Physical Properties |

|---|---|

|

|

<div class="new-fform">

</div>