![]() 9 Dec 2023

9 Dec 2023

These industries use minerals as a raw material. Some industries use ferrous metallic minerals which contain ferrous (iron), such as iron and steel industries but some use non-ferrous metallic minerals, such as aluminium, copper and jewellery industries. Many industries use non-metallic minerals such as cement and pottery industries.

Here’s a brief overview of industries that use ferrous and non-ferrous metallic minerals

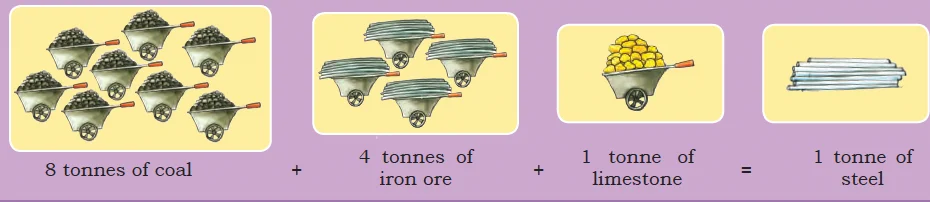

Process of obtaining steel

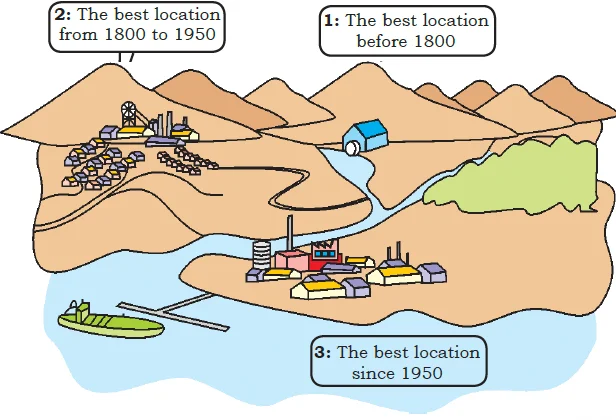

Changing location of the iron and steel industry

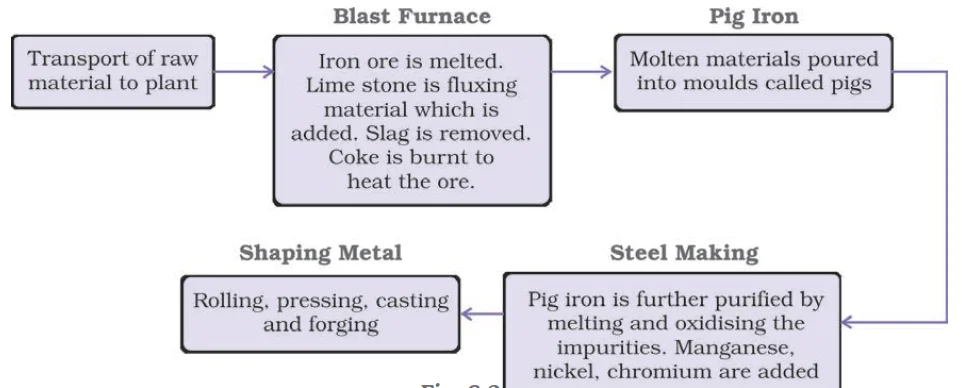

Process of Manufacture of Steel

|

Case Study on Jamshedpur and Pittsburg Jamshedpur:

|

|---|

|

Pittsburg:

|

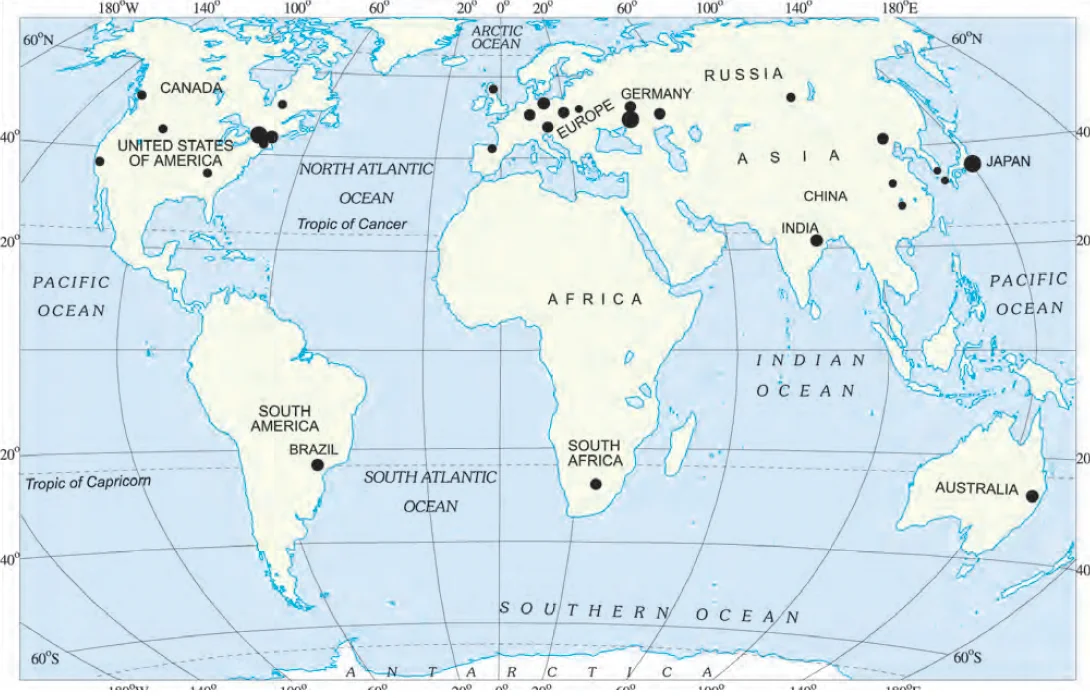

World: Major Iron Ore Producing Areas

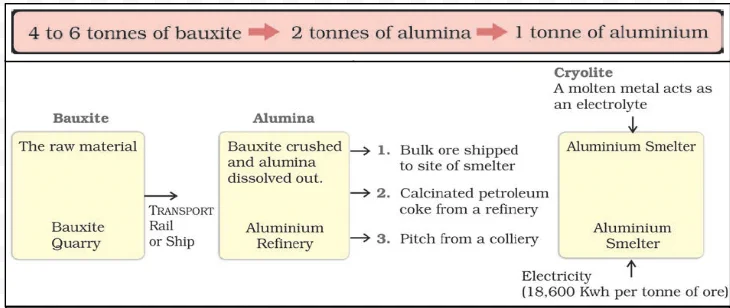

Aluminium Smelting: Harnessing Light, Resilient, and Versatile Metal for Modern Industries

|

Do You Know? Bauxite, the raw material used in the smelters during manufacturing Aluminium is a very bulky, dark reddish coloured rock. |

|---|

Process of Manufacturing in Aluminium Industry

Nourishing Growth: The Vital Role of the Fertilizer Industry in Agriculture

Also Read: Mitigating Industrial Pollution: Strategies, Impact, Solutions for Environmental Preservation

<div class="new-fform">

</div>