India’s ambition to install 500 GW non-fossil fuel capacity by 2030 relies heavily on PLI schemes to boost domestic manufacturing in solar photovoltaics and battery storage. While successful in telecom, performance in green technologies exposes structural and implementation challenges.

PLI as the Industrial Engine for Energy Transition

- Design of the PLI Scheme: The PLI model rewards firms only after they meet pre-agreed annual sales targets, linking incentives directly to performance.

- Policy Expectation: Ministries expect PLI to transform India from a net importer of green technologies into a global manufacturing hub, replicating the telecom success story.

- Sectoral Difference: Unlike telecom, green manufacturing involves deeper technological complexity and longer gestation periods.

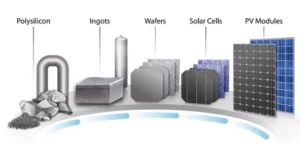

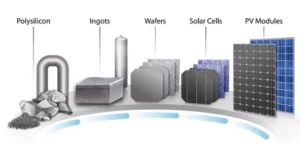

Solar Manufacturing- Downstream Success, Upstream Bottlenecks

- Robust Module Assembly: Downstream solar module manufacturing achieved about 56% of its target by mid-2025, indicating strength in assembly-stage production.

- Weak Upstream Capacity: Polysilicon and wafer manufacturing, the most technology-intensive segments, reached only 14% and 10% of their respective targets.

- Import Dependence: The imbalance reflects continued reliance on imported raw materials and foreign technical expertise.

- Policy Response: The government is considering additional capital subsidies to de-risk high-capex upstream investments.

Battery Manufacturing- Slow Progress despite Large Outlay

- Ambitious Target: The PLI scheme aims to establish 50 GWh of domestic battery cell capacity with an outlay of ₹18,000 crore to support electric mobility.

- Limited Capacity Addition: By late 2025, only 1.4 GWh (2.8%) of the targeted capacity had been commissioned.

- Technology-Heavy Production: Battery cell manufacturing requires complex gigafactory-scale infrastructure, posing high technical and execution risks.

Structural Constraints in Battery PLI

- Stringent Value Addition Norms: Mandatory 25% domestic value addition within two years and 60% within five years have slowed implementation.

- Skilled Labour Shortage: Restrictions on Chinese technical experts, who possess critical know-how, have delayed plant setup.

- Execution Penalties: Several firms face financial penalties for missing commissioning deadlines under the PLI framework.

Limits of Capital Subsidies

- Misplaced Policy Assumption: The expectation that capital support alone can accelerate high-technology manufacturing is flawed.

- Long Gestation Reality: Building capabilities in advanced materials, process engineering, and quality control requires decades of R&D investment and workforce training.

- Uncertain Technology Transfers: Dependence on international technology transfers is capital-intensive and does not always yield quick results.

Need for Course Correction

- Capability over Balance Sheets: Current PLI selection criteria prioritise net worth and financial capacity over technical expertise.

- Reorientation Required: The scheme must focus more on process know-how, skilled manpower, and technology depth.

- Sustainable Industrialisation: Without strengthening upstream capabilities, India risks remaining an assembly hub rather than a manufacturing powerhouse.

Conclusion

India’s PLI scheme has boosted green manufacturing intent, but outcomes in solar and battery technologies reveal a gap between policy ambition and technological capacity. Achieving energy transition goals requires recalibrated incentives focused on expertise, innovation, and long-term capability building, not just financial inducements.

![]() 28 Jan 2026

28 Jan 2026